body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

In the quest for energy efficiency and sustainable building practices, thermally insulated steel profiles have emerged as a game-changer. These innovative materials combine the strength and durability of steel with the insulating properties of specialized materials, offering a compelling solution for a wide range of applications. This comprehensive guide delves into the world of thermally insulated steel profiles, exploring their benefits, applications, manufacturing processes, and future trends.

Understanding the Core: How Thermally Insulated Steel Profiles Work

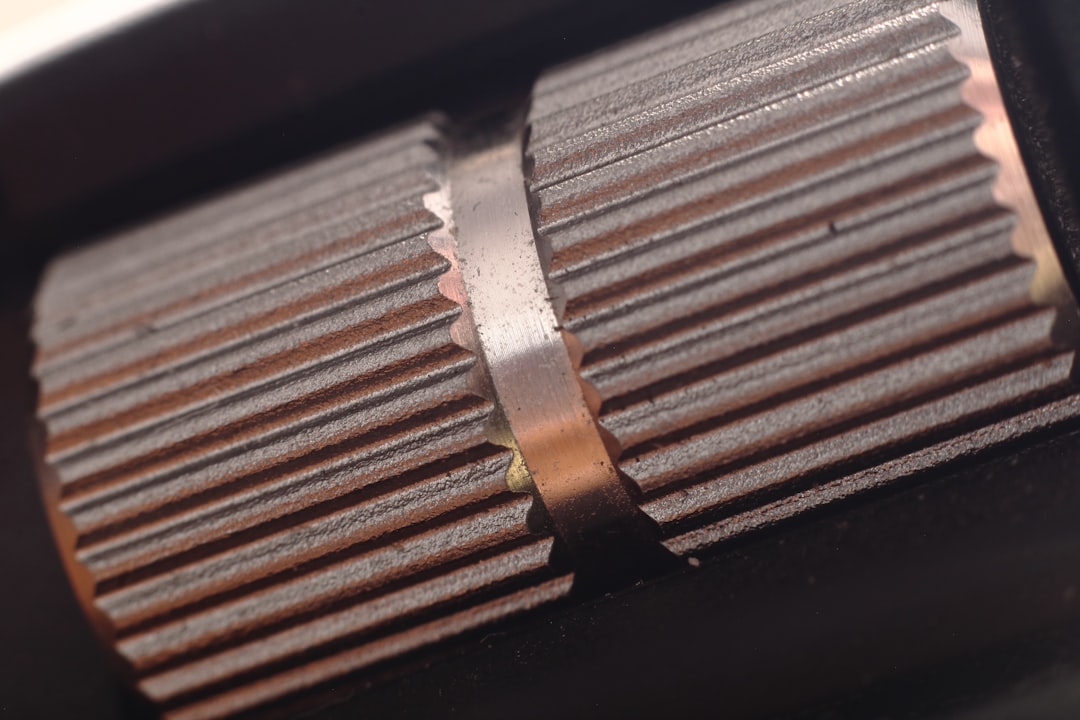

Thermally insulated steel profiles achieve their superior thermal performance through a clever combination of materials. Typically, a steel profile forms the core, providing structural strength and rigidity. This core is then encased in a layer of high-performance insulation, often polyurethane, polyisocyanurate, or mineral wool. This insulation acts as a barrier, significantly reducing the transfer of heat through the profile. Finally, an outer layer, often steel or another suitable material, protects the insulation and provides a finished aesthetic. The effectiveness of the insulation is measured by its thermal conductivity (λ-value), with lower values indicating better insulation.

Unleashing the Benefits: Why Choose Thermally Insulated Steel Profiles?

The advantages of thermally insulated steel profiles extend beyond simply improved energy efficiency. They offer a compelling combination of benefits, including:

- Enhanced Energy Efficiency: By significantly reducing heat transfer, these profiles contribute to lower heating and cooling costs, reducing a building’s overall carbon footprint.

- Improved Thermal Comfort: Minimizing temperature fluctuations within the building leads to a more comfortable indoor environment, reducing drafts and temperature gradients.

- Increased Structural Strength: The steel core provides exceptional strength and durability, making these profiles suitable for various applications, even in demanding environments.

- Reduced Condensation: The thermal break provided by the insulation helps to prevent condensation, minimizing the risk of mold and mildew growth.

- Versatile Applications: These profiles are used in a wide range of applications, from window frames and doors to curtain walls and facades.

- Long Lifespan: The durable nature of both the steel and the insulation contributes to a longer lifespan compared to some alternative materials.

Manufacturing Magic: The Process Behind Thermally Insulated Steel Profiles

The manufacturing process of thermally insulated steel profiles involves several key steps. First, the steel profile is formed using processes like rolling or extrusion. Then, the insulation material is applied, often through a continuous process involving spraying or injection molding. This ensures a complete and even coverage of the steel core. Finally, the outer layer is added, typically through a similar process, resulting in a finished profile with a sealed insulation core. Precision and quality control are crucial throughout the entire process to guarantee consistent thermal performance and structural integrity.

Performance Parameters: Measuring the Thermal Efficiency

The thermal performance of thermally insulated steel profiles is primarily characterized by their U-value (or sometimes k-value). The U-value represents the rate of heat transfer through the profile, expressed in W/m²K. A lower U-value indicates better insulation. Other important parameters include the thermal transmittance (Ψ-value) at the connections and the linear thermal transmittance (ψ-value) at the edges of the profile. These values are crucial for accurate building energy modeling and ensuring optimal energy performance of the entire building envelope.

Future Trends and Innovations in Thermally Insulated Steel Profiles

The field of thermally insulated steel profiles is constantly evolving. Ongoing research focuses on developing even more effective insulation materials, exploring innovative manufacturing techniques to reduce costs and improve efficiency, and integrating smart technologies for enhanced building performance monitoring and control. We can expect to see more sustainable materials used in the manufacturing process, further minimizing environmental impact. The integration of advanced materials and technologies promises to lead to even more efficient and durable thermally insulated steel profiles in the years to come.

In conclusion, thermally insulated steel profiles represent a significant advancement in building technology, offering a compelling blend of structural integrity, energy efficiency, and sustainability. Their versatility and performance benefits make them a valuable asset in modern construction, contributing to a more comfortable and environmentally responsible built environment.

SEO Tags:

- Thermally Insulated Steel Profiles

- Energy Efficient Steel Profiles

- Steel Window Frames Insulation

- Building Envelope Insulation

- Sustainable Construction Materials