The steel industry, a cornerstone of global infrastructure, is undergoing a significant transformation driven by advancements in industrial networking. From the raw material extraction to the final product delivery, robust and reliable communication networks are no longer a luxury but a necessity for efficiency, safety, and competitiveness. This post delves into the crucial role of industrial networking in the modern steel trade.

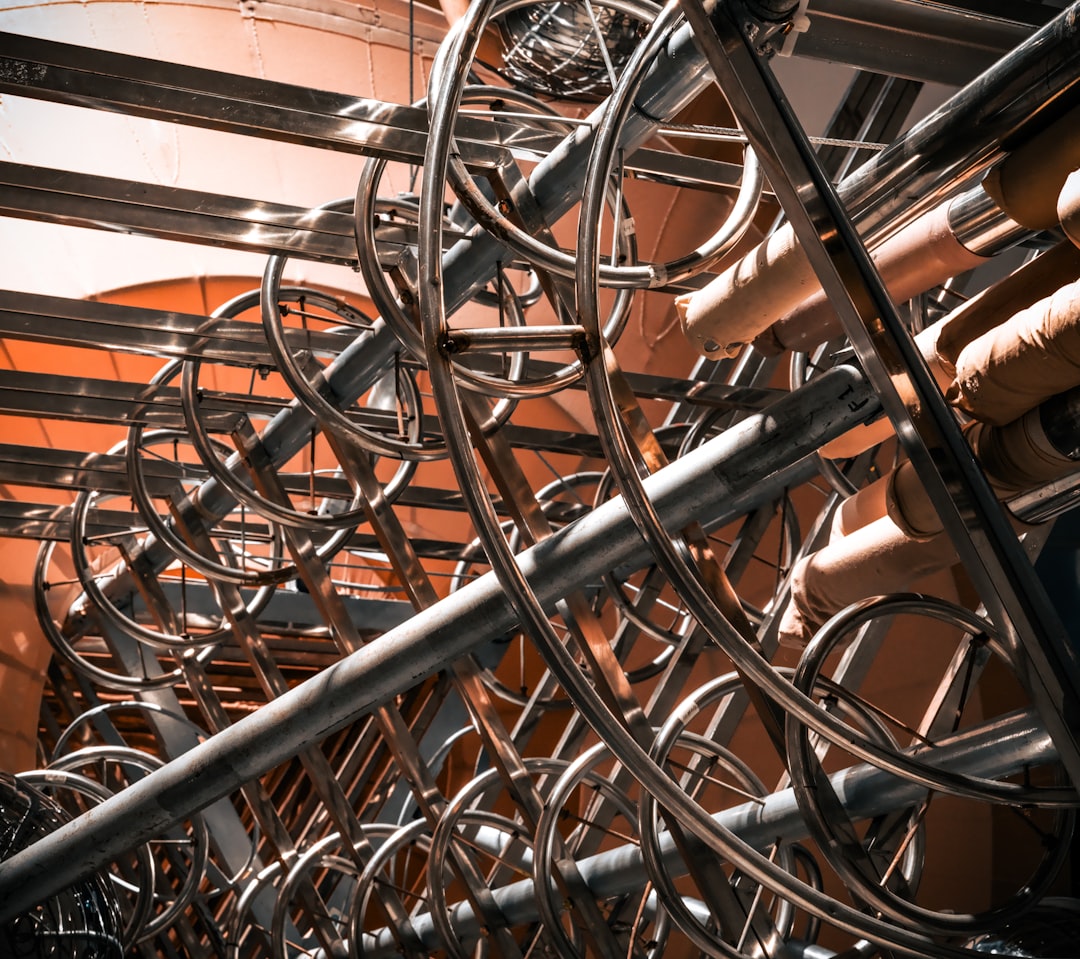

Optimizing Steel Production with Industrial Ethernet

The heart of steel production lies in its complex and demanding processes. Industrial Ethernet, with its high bandwidth and deterministic capabilities, plays a pivotal role in optimizing these processes. Real-time data acquisition from sensors embedded within blast furnaces, converters, and rolling mills provides crucial insights into temperature, pressure, and material flow. This data is then used by sophisticated control systems to adjust parameters, minimize waste, and ensure consistent product quality. Technologies like PROFINET, EtherCAT, and Modbus TCP are commonly employed, offering different levels of performance and cost-effectiveness depending on the specific application. The integration of these networks allows for precise control over the entire production line, leading to increased throughput and reduced production costs.

Enhancing Supply Chain Management through Industrial IoT

The steel trade extends far beyond the factory floor. The Industrial Internet of Things (IIoT) connects various stages of the supply chain, from raw material sourcing to finished product delivery. Smart sensors on trucks and railway cars provide real-time location tracking and condition monitoring, enabling proactive maintenance and preventing delays. Predictive analytics, powered by the vast amount of data collected by IIoT devices, allows for better forecasting of demand and optimized inventory management. This integrated approach ensures efficient material flow, reduces lead times, and improves overall supply chain visibility and resilience. The use of cloud platforms further enhances data analysis and collaboration between different stakeholders across the supply chain.

Implementing Predictive Maintenance for Increased Uptime

Unscheduled downtime in steel production is extremely costly. Industrial networking facilitates predictive maintenance by enabling continuous monitoring of critical equipment. Sensors collect data on vibration, temperature, and other key parameters, which are analyzed using machine learning algorithms to predict potential failures. This allows for proactive maintenance interventions, minimizing downtime and extending the lifespan of equipment. By identifying potential problems before they occur, companies can avoid costly repairs and production disruptions, improving overall operational efficiency and profitability. The data-driven insights gained through predictive maintenance contribute significantly to reducing operational expenditure.

Ensuring Cybersecurity in a Connected Steel Mill

With the increasing reliance on interconnected systems, cybersecurity is paramount in the steel industry. Industrial networks are vulnerable to cyberattacks that can disrupt operations, compromise sensitive data, and even cause physical damage. Robust cybersecurity measures, including firewalls, intrusion detection systems, and access control mechanisms, are essential to protect the network infrastructure. Regular security audits and employee training are vital to mitigate risks and ensure the integrity and confidentiality of data. Implementing a layered security approach, which combines network security, endpoint security, and application security, is crucial for a comprehensive defense strategy. Furthermore, adhering to industry best practices and standards, such as ISA/IEC 62443, is critical for maintaining a secure operational environment.

The Future of Industrial Networking in Steel: 5G and Beyond

The future of industrial networking in the steel trade is bright, with emerging technologies promising even greater efficiency and innovation. 5G cellular technology, with its high bandwidth and low latency, is poised to revolutionize industrial communication. 5G will enable the seamless integration of more sensors and devices, facilitating real-time data exchange and advanced automation capabilities. Furthermore, the convergence of IT and OT (Operational Technology) networks will further enhance data analysis and decision-making. Artificial intelligence (AI) and machine learning (ML) will play an increasingly important role in optimizing processes, predicting failures, and improving overall productivity. The integration of edge computing will also allow for faster processing of data closer to the source, minimizing latency and improving real-time responsiveness.

In conclusion, industrial networking is no longer an optional add-on but a fundamental requirement for success in the modern steel trade. By embracing advanced networking technologies and implementing robust cybersecurity measures, steel companies can unlock significant improvements in efficiency, productivity, and profitability, ensuring their competitiveness in a rapidly evolving global market.

SEO Tags:

Industrial Networking, Steel Industry Automation, Steel Trade Technology, IIoT in Steel, Predictive Maintenance Steel