body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

Electric Resistance Welded (ERW) pipes are a cornerstone of modern construction and industrial applications. Their versatility, cost-effectiveness, and robust performance make them a preferred choice across numerous sectors. This comprehensive guide delves into the intricacies of ERW pipes, exploring their manufacturing process, diverse applications, advantages, limitations, and future trends.

The Manufacturing Process of ERW Pipes: A Step-by-Step Look

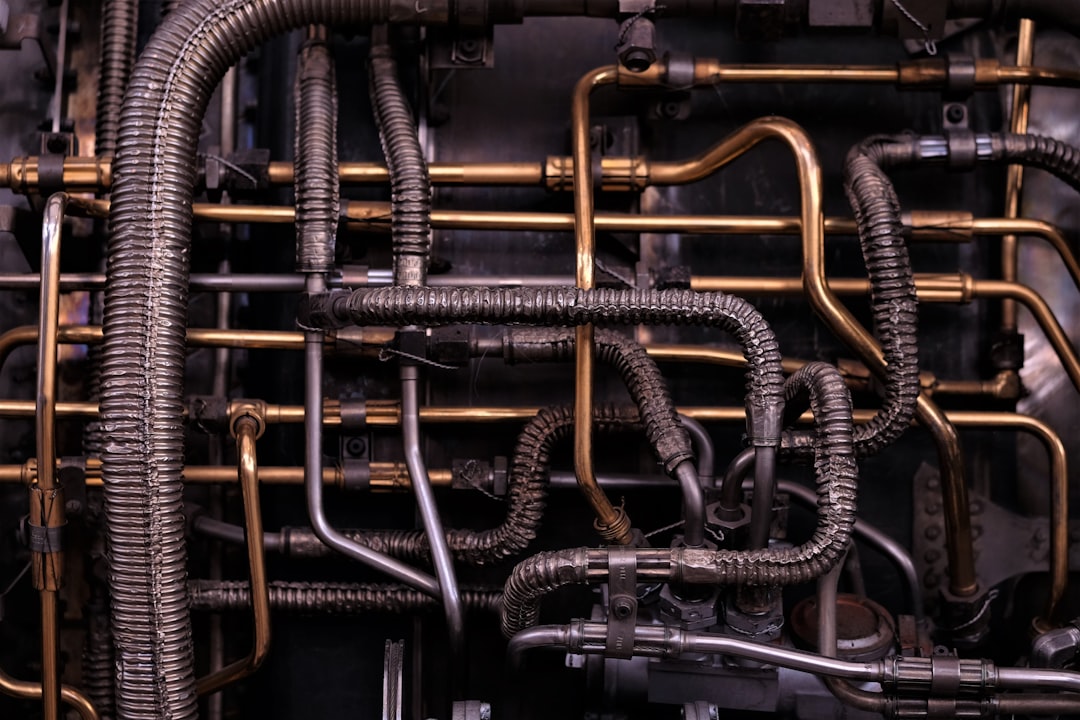

The creation of ERW pipes involves a sophisticated process that ensures high-quality, consistent results. It begins with a steel strip, precisely coiled and fed into a forming mill. Here, the strip is gradually shaped into a cylindrical form, using rollers that progressively reduce its diameter. The edges of the formed cylinder are then carefully aligned and brought together. This is where the “electric resistance welding” comes into play. A high current is passed through the seam, heating it to its welding point. Simultaneously, pressure is applied to forge a solid weld, resulting in a seamless pipe. The welded pipe then undergoes a series of quality checks, including non-destructive testing (NDT), to ensure its integrity before being sized and finished to the required specifications. Advanced manufacturing techniques allow for the creation of ERW pipes with varying diameters, wall thicknesses, and lengths, catering to the specific requirements of different applications.

Diverse Applications of ERW Pipes Across Industries

The strength and versatility of ERW pipes contribute to their widespread use across a range of industries. In construction, they serve as crucial components in scaffolding, structural frameworks, and water and gas pipelines. The automotive industry utilizes ERW pipes in exhaust systems and chassis components. The oil and gas sector relies on ERW pipes for transporting hydrocarbons, often in harsh and demanding environments. Agricultural applications include irrigation systems and structural supports. Furthermore, ERW pipes find applications in mechanical engineering for hydraulic systems, pneumatic lines, and other industrial processes. Their adaptability to different diameters and wall thicknesses makes them suitable for various pressure and load requirements.

Advantages of ERW Pipes: Why They’re a Popular Choice

Several key advantages contribute to the popularity of ERW pipes. Firstly, they offer a high strength-to-weight ratio, making them efficient for structural applications. Their cost-effectiveness compared to other pipe types, such as seamless pipes, makes them a financially attractive option for large-scale projects. The consistent quality achieved through the manufacturing process ensures reliable performance. ERW pipes are also highly customizable, with manufacturers able to produce pipes with varying dimensions and specifications. Finally, their durability and resistance to corrosion (especially with appropriate coatings) make them suitable for long-term use in various environments.

Limitations of ERW Pipes: Understanding the Drawbacks

While ERW pipes possess numerous advantages, it’s crucial to acknowledge their limitations. The welding process can potentially create a zone of slightly reduced strength at the weld seam. However, advancements in welding technology have significantly minimized this concern. Furthermore, the quality of the ERW pipe is heavily dependent on the quality of the steel strip used in the manufacturing process. Poor quality steel can result in inferior pipes. Proper inspection and quality control measures are therefore essential. Finally, some applications may necessitate seamless pipes due to stringent requirements regarding the absence of welds. Careful consideration of the specific application is crucial in deciding whether ERW pipes are the most suitable choice.

Future Trends in ERW Pipe Manufacturing and Applications

The future of ERW pipes is promising, driven by technological advancements and evolving industry needs. Advanced welding techniques are leading to even stronger and more consistent welds. The use of high-strength low-alloy (HSLA) steels enhances the durability and performance of ERW pipes. Automation and robotics are improving manufacturing efficiency and reducing costs. Furthermore, research into new coatings and surface treatments is enhancing the corrosion resistance of ERW pipes. Finally, as sustainability becomes increasingly important, the focus on using recycled steel and reducing manufacturing waste will continue to shape the future of ERW pipe production. These advancements will ensure that ERW pipes remain a vital component across diverse industries for years to come.

In conclusion, ERW pipes represent a reliable and versatile solution for a wide array of applications. Understanding their manufacturing process, advantages, and limitations is crucial for making informed decisions in engineering, construction, and other relevant fields. The ongoing advancements in manufacturing technology promise even greater efficiency and performance in the years to come.

SEO Tags:

- ERW Pipe

- Electric Resistance Welded Pipe

- Steel Pipe Applications

- Welded Steel Pipe

- ERW Pipe Manufacturing