In industries where equipment faces harsh environments and significant impact forces, the reliability of connection systems is paramount. A failure in a connection can lead to catastrophic consequences, from equipment malfunction to complete system failure. This is where shock-resistant connection systems become crucial. This blog post delves into the design, applications, testing, and future of these vital components.

Understanding the Need for Shock-Resistant Connections

Shock-resistant connection systems are designed to withstand sudden, high-magnitude forces. These forces can stem from various sources, including impacts, vibrations, and sudden accelerations. Traditional connection methods, like simple bolts and screws, often prove inadequate in these scenarios. The consequences of failure can be severe, ranging from minor malfunctions to complete system destruction, potentially leading to injury or significant financial losses. Industries such as aerospace, automotive, military, and construction rely heavily on these robust systems to ensure the safety and reliability of their equipment and infrastructure.

The design of a shock-resistant connection must consider factors like the magnitude and duration of the expected impact, the materials involved, and the overall system geometry. It’s not simply about using stronger materials; it’s about a holistic approach that encompasses material selection, joint design, and manufacturing techniques. The goal is to distribute the impact energy effectively and prevent failure mechanisms like fatigue, fracture, or disengagement.

Design Principles of Shock-Resistant Connections

Several design principles contribute to the shock resistance of connection systems. These include:

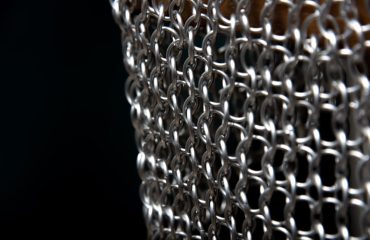

- Material Selection: High-strength materials like titanium alloys, high-strength steel, and advanced composites are often employed. These materials possess high yield strength and fatigue resistance, enabling them to withstand significant impact loads.

- Redundancy: Incorporating multiple connection points or utilizing backup systems adds redundancy to the design. If one connection fails, others can compensate, preventing complete system failure.

- Energy Absorption Mechanisms: Designing connections to absorb impact energy is critical. This can be achieved through features like compliant elements (e.g., elastomers or springs), which dissipate energy through deformation, or through the use of materials with high energy absorption capacity.

- Geometric Design: The geometry of the connection plays a crucial role. Features like tapered joints, interlocking designs, and optimized contact areas help distribute stress more effectively and prevent stress concentration points, which are common failure locations.

- Friction and Locking Mechanisms: Incorporating friction and locking mechanisms helps prevent disengagement under shock loads. This might involve using specialized fasteners, locking pins, or interference fits.

Applications of Shock-Resistant Connection Systems

The applications of shock-resistant connection systems are widespread across diverse industries. Some key examples include:

- Aerospace: Securing critical components in aircraft and spacecraft, where impacts from turbulence, landing, and launch are significant.

- Automotive: Connecting structural components in vehicles to withstand collisions and impacts from road hazards.

- Military: Connecting components in armored vehicles and weapons systems to endure extreme shock and vibration.

- Construction: Securing structural elements in buildings and bridges to withstand seismic activity and other extreme events.

- Robotics: Connecting joints and components in robots to handle impacts and vibrations during operation.

Testing and Validation of Shock-Resistant Connections

Rigorous testing is essential to validate the performance of shock-resistant connection systems. Various methods are employed, including:

- Drop Tests: Simulating impacts by dropping the connected components from a specified height.

- Shock Tube Tests: Exposing connections to controlled shock waves to evaluate their response to sudden pressure changes.

- Vibration Tests: Subjecting connections to various frequencies and amplitudes of vibration to assess fatigue resistance.

- Finite Element Analysis (FEA): Using computer simulations to predict the behavior of connections under various load conditions, optimizing designs before physical testing.

- Accelerated Life Testing: Subjecting connections to accelerated cycles of loading and unloading to simulate long-term performance under real-world conditions.

Future Trends in Shock-Resistant Connection Systems

The field of shock-resistant connection systems is constantly evolving. Future trends include:

- Smart Connections: Integrating sensors and electronics into connections to monitor their health and performance in real-time, allowing for predictive maintenance.

- Advanced Materials: Utilizing new materials with enhanced strength, toughness, and energy absorption capabilities, such as carbon nanotubes and graphene-reinforced composites.

- Additive Manufacturing: Employing 3D printing techniques to create complex and customized connection designs with optimized geometries for enhanced shock resistance.

- Self-Healing Materials: Developing connections using self-healing materials that can repair minor damage autonomously, extending their lifespan and reliability.

- Bio-inspired Designs: Studying natural systems to discover new design principles for shock-resistant connections, inspired by the resilience of biological structures.

In conclusion, shock-resistant connection systems are critical components in countless applications, ensuring safety and reliability in challenging environments. Ongoing research and development are pushing the boundaries of what’s possible, leading to even more robust and versatile connection technologies in the future.

Tags: Shock resistant connections, impact resistant fasteners, vibration damping, connection systems design, aerospace engineering