In the heart of every manufacturing facility beats a network of industrial pipes, silently facilitating the flow of crucial materials and processes. The choice of these pipes is far from trivial; it directly impacts efficiency, safety, and the bottom line. This comprehensive guide delves into the critical considerations when selecting industrial pipes for your manufacturing operation.

1. Material Matters: Choosing the Right Pipe for the Job

The material of your industrial pipes is paramount. Different materials offer varying levels of durability, corrosion resistance, temperature tolerance, and pressure handling capabilities. Common choices include:

- Carbon Steel: A cost-effective option widely used for its strength and weldability. Suitable for applications with moderate pressures and temperatures, but susceptible to corrosion in certain environments. Requires proper coating or lining for protection.

- Stainless Steel: Offers superior corrosion resistance and can withstand higher temperatures and pressures than carbon steel. Various grades (e.g., 304, 316) cater to specific needs. More expensive than carbon steel but offers long-term cost savings due to extended lifespan.

- Ductile Iron: Known for its high tensile strength and excellent ductility, making it resistant to impact and vibration. A good choice for underground piping and applications requiring high pressure resistance.

- PVC (Polyvinyl Chloride): A lightweight, corrosion-resistant plastic pipe ideal for handling chemicals and wastewater. However, it has limitations in terms of temperature and pressure tolerance.

- CPVC (Chlorinated Polyvinyl Chloride): Offers improved temperature resistance compared to PVC, making it suitable for hot water applications.

The selection process should carefully consider the specific fluids being transported, the operating temperature and pressure, the environmental conditions, and the overall budget.

2. Pipe Size and Diameter: Optimizing Flow and Efficiency

Determining the appropriate pipe size and diameter is crucial for maximizing flow efficiency and minimizing pressure drop. Undersized pipes can lead to increased pressure, energy consumption, and potential blockages. Oversized pipes, while reducing pressure drop, are more expensive and may require more support structures.

Factors influencing pipe size selection include:

- Flow rate: The volume of fluid to be transported per unit time.

- Fluid viscosity: The thickness or resistance to flow of the fluid.

- Pipe length: Longer pipes experience greater frictional losses.

- Elevation changes: Changes in elevation affect pressure and flow.

Hydraulic calculations are often employed to determine the optimal pipe size for a given application. Consulting with a piping engineer is recommended for complex systems.

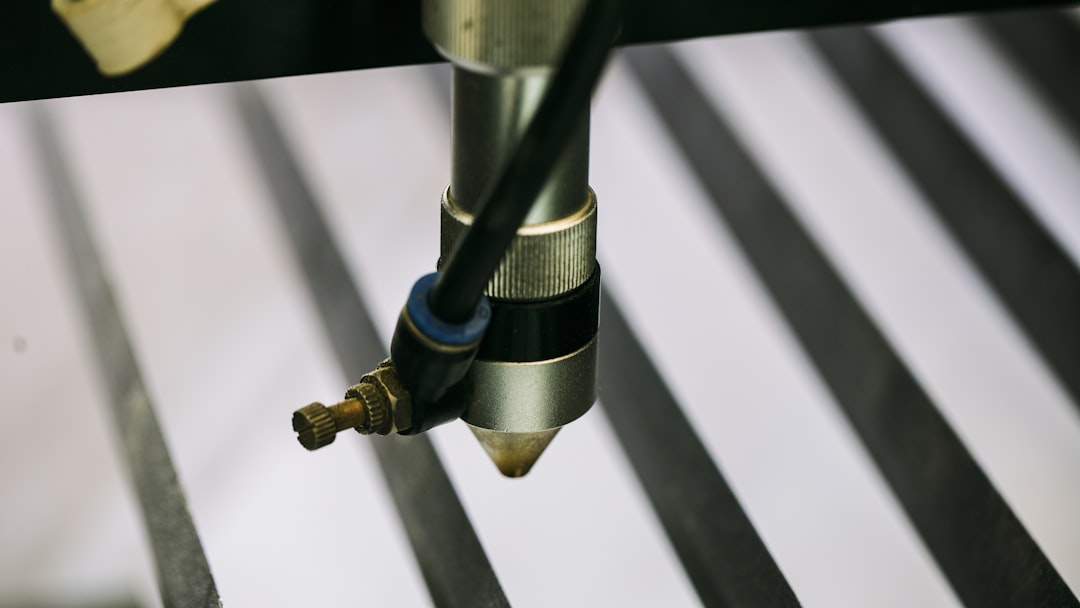

3. Industrial Pipe Fittings and Connections: Ensuring a Leak-Free System

Industrial pipe fittings are essential components that connect pipes, change direction, or regulate flow. The choice of fittings is crucial for system integrity and leak prevention. Common types of fittings include:

- Elbows: Used to change the direction of the pipe.

- Tees: Used to branch off from a main pipe.

- Flanges: Used to connect pipes using bolts and gaskets.

- Unions: Used to connect and disconnect pipes easily.

- Valves: Used to control the flow of fluids.

The selection of fittings should consider the material compatibility with the pipes, the pressure rating, and the ease of installation and maintenance. Proper welding or threading techniques are essential to ensure leak-free connections.

4. Regulations and Compliance: Meeting Industry Standards

Industrial piping systems are subject to various regulations and standards aimed at ensuring safety and preventing environmental hazards. Compliance with these regulations is crucial to avoid penalties and ensure the safe operation of the manufacturing facility. Relevant standards may include:

- ASME B31.1: Power Piping

- ASME B31.3: Process Piping

- API 510: Pressure Vessel Inspection Code

- OSHA regulations: Occupational Safety and Health Administration regulations related to piping systems.

Understanding and adhering to these standards is essential during the design, installation, and maintenance of industrial piping systems.

5. Maintenance and Inspection: Extending the Lifespan of Your Piping System

Regular maintenance and inspection are crucial for extending the lifespan of your industrial piping system and preventing costly failures. This includes:

- Visual inspections: Regularly checking for leaks, corrosion, and damage.

- Pressure testing: Periodically testing the system to ensure it can withstand the operating pressure.

- Non-destructive testing (NDT): Employing techniques like ultrasonic testing or radiographic testing to detect internal flaws.

- Cleaning and flushing: Removing debris and buildup from the pipes to maintain flow efficiency.

A well-maintained piping system contributes significantly to reduced downtime, improved safety, and lower operational costs.

By carefully considering these factors, manufacturers can select and maintain the optimal industrial piping system, ensuring efficient operations, enhanced safety, and long-term success.

Tags: Industrial pipes, manufacturing pipes, pipe materials, pipe fittings, piping regulations