body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 1em auto;

}

The oil and gas industry relies heavily on a complex network of pipes and equipment to successfully extract hydrocarbons from beneath the earth’s surface. Two crucial components of this system are casing and tubing, each playing a distinct yet interconnected role in ensuring safe and efficient operations. This comprehensive guide delves into the intricacies of casing and tubing, exploring their functions, materials, design considerations, and installation processes.

The Vital Role of Casing: Protecting the Wellbore

Casing is a steel pipe cemented into the wellbore, acting as a protective barrier and structural support. Its primary functions include:

- Preventing wellbore collapse: Casing provides structural integrity to the wellbore, preventing the surrounding formations from collapsing inwards, especially in unstable geological conditions.

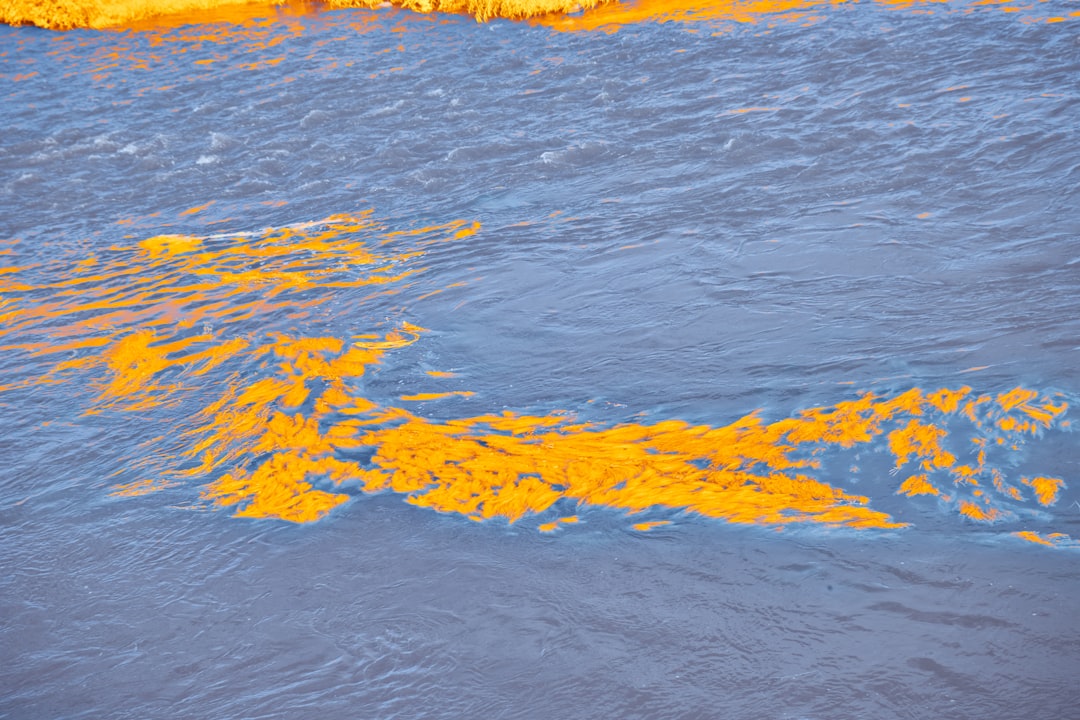

- Preventing fluid migration: It isolates different formations, preventing the mixing of fluids (water, oil, gas) from different geological strata. This is crucial for maintaining well control and preventing environmental contamination.

- Providing a pathway for production: Casing forms a conduit for the flow of hydrocarbons to the surface. It’s essential for guiding the tubing and other production equipment.

- Protecting groundwater resources: By creating a sealed barrier, casing helps prevent the contamination of freshwater aquifers by oil and gas.

Casing strings are typically made of high-strength steel, with various grades and specifications tailored to the specific well conditions, including depth, pressure, and temperature.

Tubing: The Highway for Hydrocarbons

Tubing is the smaller diameter pipe that runs inside the casing. It’s the primary conduit for transporting hydrocarbons (oil and gas) from the reservoir to the surface. Its key functions include:

- Hydrocarbon transportation: Tubing is the main pathway for oil and gas to flow from the reservoir to the surface processing facilities.

- Artificial lift support: In many wells, artificial lift methods (e.g., pumps, gas lift) are employed to enhance production. Tubing provides the necessary pathway for these systems.

- Injection of fluids: Tubing can also be used to inject fluids into the reservoir for purposes such as enhanced oil recovery or water disposal.

- Downhole tool access: Tubing provides access for downhole tools used for well maintenance, intervention, and stimulation.

Tubing is typically made of high-strength steel or other suitable materials, selected based on the well’s conditions and operational requirements. It’s crucial that the tubing is corrosion-resistant to ensure its longevity and reliability.

Casing and Tubing Materials: A Deep Dive

The selection of casing and tubing materials is critical to ensuring well integrity and operational efficiency. Common materials include various grades of steel, with the choice depending on factors like pressure, temperature, and corrosive environment. High-strength low-alloy (HSLA) steels are frequently used for their combination of strength and corrosion resistance. In particularly corrosive environments, specialized alloys like chromium-molybdenum steels or even exotic alloys may be necessary. The selection process involves careful consideration of wellbore conditions and predicted service life.

Design Considerations: Ensuring Well Integrity

Designing the casing and tubing strings requires a detailed understanding of the geological formations, anticipated pressures and temperatures, and the planned operational life of the well. Key design considerations include:

- Pressure ratings: Casing and tubing must withstand the internal and external pressures encountered throughout the well’s life.

- Temperature ratings: The materials must be able to withstand the high temperatures found in deep wells.

- Corrosion resistance: The chosen materials must be resistant to the corrosive fluids present in the wellbore.

- Collapse resistance: Casing must be strong enough to resist external pressures that could cause it to collapse.

- Burst resistance: Both casing and tubing must withstand the internal pressures from the produced hydrocarbons.

Specialized software and engineering expertise are essential for accurate casing and tubing design to ensure well integrity and safety.

Installation and Cementing: A Precise Process

The installation and cementing of casing and tubing are critical steps in well construction. Casing is run into the wellbore and cemented in place to create a secure barrier. The cementing process is crucial for isolating different formations, preventing fluid migration, and providing structural support. Tubing is then run inside the casing, completing the well’s production system. Precise procedures and quality control are essential throughout the entire process to ensure the well’s long-term performance and safety. Specialized equipment and skilled personnel are required to perform these operations efficiently and effectively.

In conclusion, casing and tubing are indispensable components in oil and gas well construction and operation. Their design, selection, and installation are crucial for ensuring well integrity, safety, and efficient hydrocarbon production. A thorough understanding of these aspects is essential for anyone involved in the oil and gas industry.

SEO Tags:

- Oil and Gas Casing

- Oil and Gas Tubing

- Wellbore Protection

- Casing Design

- Tubing Installation