Industrial machinery relies heavily on efficient and reliable fluid transfer systems. At the heart of these systems lies the humble pipe – a seemingly simple component that plays a crucial role in the smooth and safe operation of countless industrial processes. From transporting high-pressure steam in power plants to conveying delicate chemicals in pharmaceutical manufacturing, pipes are the unsung heroes of heavy industry. This comprehensive guide explores the multifaceted world of pipe usage in industrial machinery, delving into material selection, application specifics, maintenance protocols, and essential safety considerations.

1. Material Selection: Choosing the Right Pipe for the Job

The selection of pipe material is paramount, as it directly impacts the system’s longevity, safety, and efficiency. The choice depends heavily on the fluid being transported, the operating pressure and temperature, and the corrosive environment. Common materials include:

- Carbon Steel: A cost-effective option suitable for many applications, but susceptible to corrosion in certain environments. Often used for water, steam, and non-corrosive gases.

- Stainless Steel: Highly resistant to corrosion, making it ideal for handling chemicals, pharmaceuticals, and food products. Comes in various grades (e.g., 304, 316) offering varying degrees of corrosion resistance.

- Cast Iron: Durable and resistant to pressure, but prone to cracking under stress. Commonly used in drainage and wastewater systems.

- Plastic Pipes (PVC, HDPE): Lightweight, corrosion-resistant, and cost-effective. Suitable for low-pressure applications and chemical handling, but have limitations in terms of temperature and pressure resistance.

- Copper: Excellent corrosion resistance and thermal conductivity, often used in plumbing and HVAC systems.

Selecting the appropriate material requires careful consideration of all factors to ensure optimal performance and prevent costly failures.

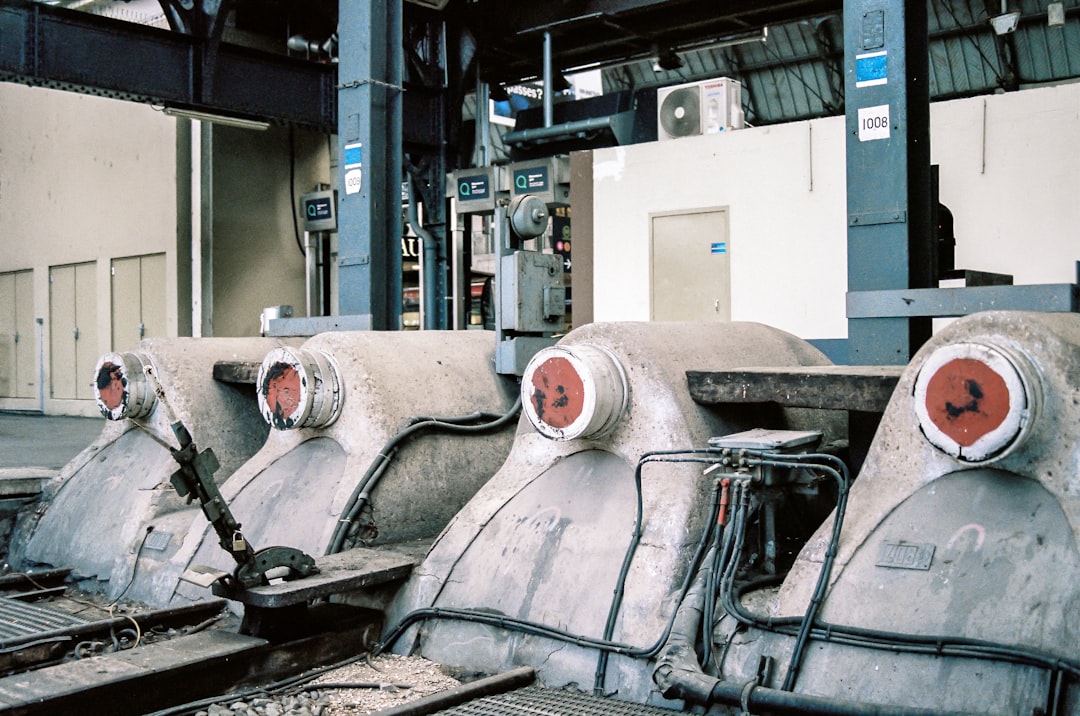

2. Pipe Applications in Diverse Industrial Settings

The applications of pipes in industrial machinery are vast and varied. Here are a few examples:

- Power Generation: High-pressure steam pipes in power plants, cooling water circulation systems, and fuel delivery lines.

- Chemical Processing: Transporting and processing various chemicals, often requiring specialized materials resistant to corrosion and high temperatures.

- Oil and Gas: Transporting crude oil, natural gas, and refined products over long distances, often involving high pressures and challenging environmental conditions.

- Pharmaceutical Manufacturing: Handling sterile fluids and pharmaceuticals, requiring highly sanitary and corrosion-resistant pipes.

- Food and Beverage Processing: Transporting liquids and gases in food and beverage production, demanding materials that meet stringent hygiene standards.

- HVAC Systems: Distributing heating and cooling fluids throughout buildings and industrial facilities.

The specific requirements for pipe materials, dimensions, and fittings vary significantly across these applications.

3. Essential Pipe Fittings and Components

Pipes rarely operate in isolation. A comprehensive piping system requires a range of fittings and components to ensure proper flow control, direction changes, and connections. These include:

- Elbows: Used to change the direction of the pipe.

- Tees: Allow for branching connections.

- Unions: Allow for easy disconnection and reconnection of pipes.

- Valves: Control the flow of fluids (gate valves, globe valves, ball valves, etc.).

- Flanges: Used to connect pipes and components using bolts.

- Reducers: Connect pipes of different diameters.

- Strainers: Remove debris from fluids.

The proper selection and installation of these components are critical to the overall performance and reliability of the piping system.

4. Maintenance and Inspection of Industrial Piping Systems

Regular maintenance and inspection are crucial for preventing leaks, failures, and ensuring the safety of personnel and equipment. This includes:

- Visual Inspections: Regularly checking for signs of corrosion, damage, or leaks.

- Pressure Testing: Periodically testing the system to ensure it can withstand operating pressures.

- Non-Destructive Testing (NDT): Using techniques like ultrasonic testing or radiography to detect internal flaws.

- Cleaning and Flushing: Regularly cleaning the pipes to remove debris and buildup.

- Repair and Replacement: Promptly repairing or replacing damaged sections of the piping system.

A well-maintained piping system significantly reduces the risk of costly downtime and safety hazards.

5. Safety Regulations and Best Practices

Safety is paramount when working with industrial piping systems. Adherence to relevant safety regulations and best practices is essential. This includes:

- Proper Design and Installation: Ensuring that the piping system is designed and installed according to industry standards and codes.

- Lockout/Tagout Procedures: Implementing safe procedures for isolating and de-energizing equipment before maintenance or repair.

- Personal Protective Equipment (PPE): Using appropriate PPE, such as safety glasses, gloves, and protective clothing.

- Emergency Response Plans: Having plans in place to handle leaks, spills, or other emergencies.

- Regular Training: Providing regular training to personnel on safe working practices and emergency procedures.

Neglecting safety can lead to serious accidents, injuries, and environmental damage.

In conclusion, the seemingly simple pipe plays a vital role in the efficient and safe operation of industrial machinery. Careful consideration of material selection, application specifics, maintenance protocols, and safety regulations is crucial for ensuring the longevity and reliability of these critical systems. By understanding these aspects, industries can optimize their processes and minimize the risk of costly failures and safety incidents.

Tags: industrial piping, industrial machinery, pipe usage, pipe materials, pipe maintenance