The unobtrusive networks of water and gas pipes beneath our streets are vital lifelines, ensuring the smooth functioning of our homes and businesses. However, the reliability and safety of these systems hinge on adherence to stringent quality standards. From the materials used to the rigorous testing procedures employed, maintaining these standards is paramount to preventing leaks, bursts, and potentially hazardous situations. This post delves into the crucial aspects of quality control in water and gas pipe infrastructure.

Material Matters: Choosing the Right Stuff for Water and Gas Pipes

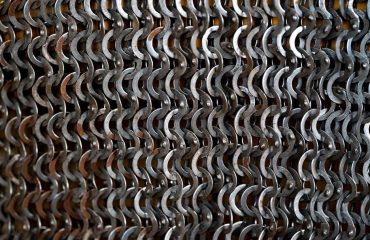

The choice of material significantly impacts a pipe’s lifespan, durability, and resistance to corrosion. Water pipes commonly utilize materials like copper, PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), polyethylene (PE), and ductile iron. Each material possesses unique properties: Copper offers excellent corrosion resistance and longevity but can be expensive. PVC and CPVC are cost-effective and corrosion-resistant but have lower temperature tolerances. PE is flexible and suitable for underground applications, while ductile iron provides high strength and durability, particularly for larger diameter pipes. Gas pipes, due to the flammability of natural gas, often employ high-density polyethylene (HDPE), steel (often coated for corrosion protection), and sometimes cast iron for specific applications. The selection process considers factors like pressure, temperature, soil conditions, and the intended lifespan of the pipeline.

Rigorous Testing: Ensuring Pipeline Integrity

Once the pipe materials are selected, rigorous testing is crucial to ensure they meet the specified quality standards. These tests vary depending on the material and intended application. For instance, water pipes undergo pressure tests to determine their burst strength and resistance to leakage. Non-destructive testing methods, such as ultrasonic testing and radiographic testing, are employed to detect internal flaws or weaknesses without damaging the pipe. Gas pipes undergo similar pressure testing, often at higher pressures to account for the potential energy of the gas. Furthermore, leak detection tests are essential to identify any potential points of failure. These tests are conducted at various stages of the manufacturing process and before installation to guarantee that the pipes conform to the required standards.

Regulatory Compliance: Navigating the Legal Landscape of Pipeline Installation

The installation and maintenance of water and gas pipes are subject to a complex web of regulations and codes designed to ensure public safety and prevent environmental damage. These regulations vary by jurisdiction but often incorporate national or international standards, such as those published by organizations like ASTM International (American Society for Testing and Materials) and ISO (International Organization for Standardization). These standards specify acceptable materials, installation practices, and testing procedures. Compliance with these regulations is mandatory, and failure to adhere to them can result in significant penalties and legal repercussions. Regular inspections and maintenance are also mandated to ensure the continued integrity of the pipelines.

The Impact of Poor Quality: Understanding the Consequences

The consequences of using substandard materials or failing to adhere to quality standards can be severe. Leaks in water pipes can lead to water damage, property damage, and costly repairs. In the case of gas pipes, leaks can pose a significant fire hazard and even lead to explosions. Furthermore, poor quality pipes can contribute to premature failure, requiring costly replacements and disruption to service. The long-term economic and social costs associated with inadequate pipeline infrastructure far outweigh the initial investment in quality materials and proper installation techniques. This underscores the importance of prioritizing quality control throughout the entire pipeline lifecycle.

Advanced Technologies: Enhancing Pipeline Performance and Safety

Technological advancements are continuously improving the quality and safety of water and gas pipes. Smart sensors embedded within pipes can monitor pressure, flow rate, and temperature in real-time, providing early warnings of potential problems. Advanced leak detection systems can pinpoint leaks quickly and accurately, minimizing damage and downtime. The use of new materials, such as composite pipes and advanced polymers, is expanding the range of options for pipeline construction, offering improved durability, corrosion resistance, and flexibility. These technological innovations are crucial in enhancing the reliability and safety of water and gas distribution networks, contributing to a more sustainable and resilient infrastructure.

In conclusion, maintaining high quality standards in water and gas pipes is not merely a matter of cost-effectiveness; it’s a critical aspect of ensuring public safety, protecting the environment, and maintaining the essential services that underpin modern life. By adhering to strict material specifications, rigorous testing protocols, and comprehensive regulatory frameworks, we can ensure the longevity, reliability, and safety of these vital lifelines for generations to come.

Tags: water pipes, gas pipes, pipeline safety, plumbing regulations, pipe materials