The world of engineering is constantly seeking materials that offer superior strength, durability, and lightweight properties. One innovative solution gaining traction is the use of carbon fiber coatings on steel pipes. This combination leverages the inherent strength of steel with the remarkable properties of carbon fiber, creating a composite material with exceptional characteristics. This post delves into the fascinating world of carbon fiber-coated steel pipes, exploring their benefits, applications, and future potential.

Unveiling the Superior Strength of Carbon Fiber-Coated Steel Pipes

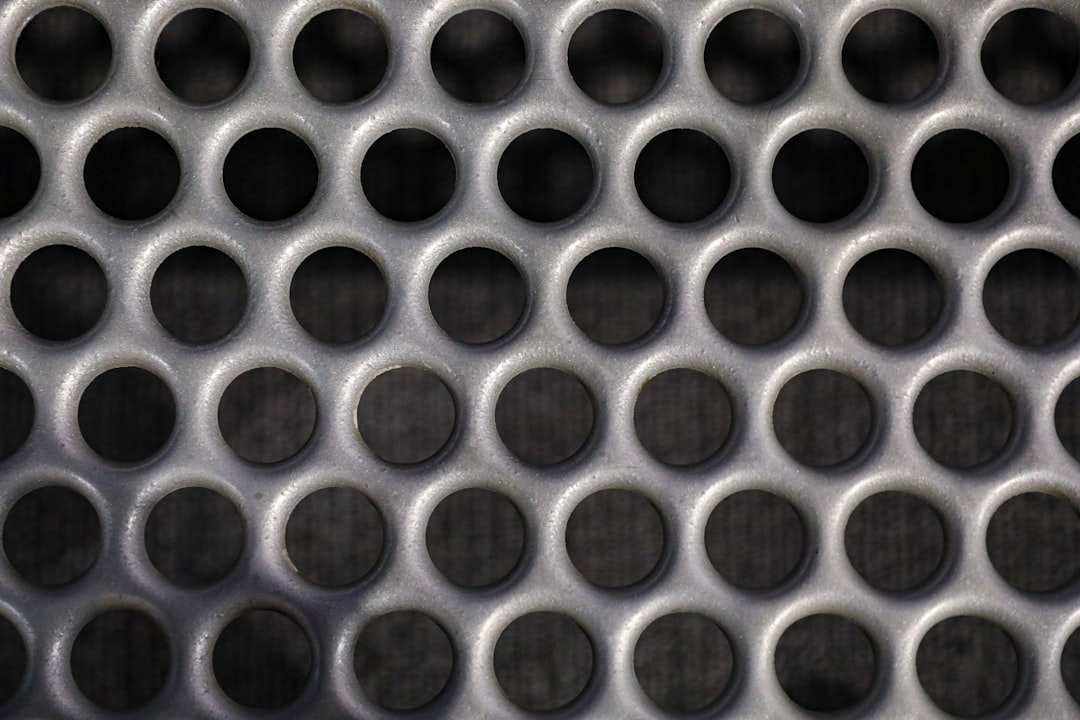

Steel pipes, a mainstay in various industries, possess inherent strength but can be susceptible to corrosion, fatigue, and weight limitations. The addition of a carbon fiber coating significantly enhances these aspects. Carbon fiber, known for its incredibly high tensile strength-to-weight ratio, acts as a protective layer and a reinforcement mechanism. This composite structure distributes stress more effectively, resulting in increased load-bearing capacity and resistance to bending and buckling. The carbon fiber coating not only adds strength but also improves the overall fatigue life of the steel pipe, making it more resistant to repeated stress cycles. This is particularly beneficial in applications involving dynamic loads or vibrations.

Enhanced Corrosion Resistance: Protecting Against Environmental Degradation

Corrosion is a major concern for steel pipes, especially in harsh environments. Exposure to moisture, chemicals, and extreme temperatures can lead to degradation and eventual failure. Carbon fiber coatings offer excellent protection against corrosion. The coating acts as a barrier, preventing corrosive agents from reaching the steel substrate. Furthermore, the carbon fiber itself is highly resistant to chemical attack, enhancing the overall longevity of the pipe. This increased corrosion resistance translates to reduced maintenance costs and extended service life, making carbon fiber-coated steel pipes a cost-effective solution in the long run.

Lightweight Design: Optimizing Performance and Reducing Transportation Costs

The lightweight nature of carbon fiber is a significant advantage. While providing superior strength, the carbon fiber coating adds minimal weight compared to traditional steel pipes of equivalent strength. This reduction in weight translates to several benefits. In transportation, lighter pipes mean lower fuel consumption and reduced transportation costs. In applications where the pipe is subject to movement or handling, the reduced weight makes installation and maintenance easier and safer. The lighter weight also minimizes the structural support required, leading to further cost savings in design and construction.

Diverse Applications: Where Carbon Fiber-Coated Steel Pipes Excel

The exceptional properties of carbon fiber-coated steel pipes make them suitable for a wide range of applications across various industries. They are increasingly used in:

- Oil and Gas Industry: Transporting high-pressure fluids and gases with enhanced safety and longevity.

- Chemical Processing: Handling corrosive chemicals without compromising structural integrity.

- Construction and Infrastructure: Building stronger and more durable structures, such as bridges and pipelines.

- Aerospace and Defense: Creating lightweight yet robust components for aircraft and spacecraft.

- Automotive Industry: Developing high-performance exhaust systems and other critical components.

The versatility of this composite material opens doors to innovative solutions in diverse engineering challenges.

The Future of Carbon Fiber-Coated Steel Pipes: Innovations and Advancements

Research and development in the field of carbon fiber-coated steel pipes continue to push the boundaries of material science. Ongoing efforts focus on:

- Improving the bonding between carbon fiber and steel: Ensuring optimal stress transfer and maximizing the benefits of the composite structure.

- Developing more cost-effective manufacturing processes: Making carbon fiber-coated steel pipes more accessible to a wider range of applications.

- Exploring new carbon fiber types and coating techniques: Further enhancing the properties of the composite material, such as improving impact resistance and thermal stability.

- Expanding applications into new industries: Exploring the potential of carbon fiber-coated steel pipes in emerging fields like renewable energy and advanced manufacturing.

The future looks bright for carbon fiber-coated steel pipes, with ongoing innovations promising even more impressive performance and wider adoption across various sectors.

In conclusion, carbon fiber-coated steel pipes represent a significant advancement in material science, offering a powerful combination of strength, durability, corrosion resistance, and lightweight design. Their diverse applications and ongoing advancements make them a compelling solution for engineers seeking superior performance and cost-effectiveness in a wide range of industries.

Tags: carbon fiber coated steel pipes, composite pipes, steel pipe reinforcement, corrosion resistance, lightweight pipes