Annealed wire, a type of metal wire that has undergone a heat treatment process called annealing, boasts exceptional properties that make it incredibly versatile across a broad spectrum of industries. This process significantly alters the wire’s microstructure, resulting in increased ductility, improved formability, and enhanced tensile strength. This blog post delves into the fascinating world of annealed wire, exploring its unique characteristics and diverse applications.

Understanding the Annealing Process and its Impact on Wire Properties

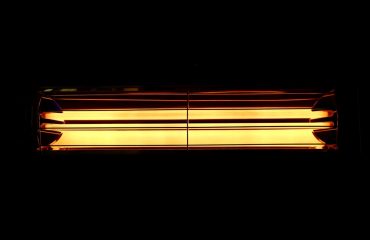

Annealing involves heating the wire to a specific temperature, holding it at that temperature for a predetermined time, and then slowly cooling it. This controlled heating and cooling cycle relieves internal stresses within the wire’s structure, softening the metal and making it more pliable. The specific annealing parameters (temperature, time, and cooling rate) are carefully controlled to achieve the desired properties in the final product. Different annealing techniques, such as stress-relief annealing, process annealing, and full annealing, are employed depending on the intended application. The result is a wire that is easier to bend, shape, and draw into intricate forms without fracturing, a crucial advantage in many manufacturing processes.

Annealed Wire in the Electrical Industry: Powering Our World

Annealed copper wire, in particular, plays a critical role in the electrical industry. Its high conductivity and excellent ductility make it ideal for various electrical applications, including:

- Wiring in buildings and infrastructure: Annealed copper wire forms the backbone of electrical systems in homes, offices, and industrial facilities, safely transmitting electricity over long distances.

- Manufacturing of electrical components: It’s used extensively in the production of transformers, motors, generators, and other electrical equipment where its ability to conduct electricity efficiently and withstand bending is paramount.

- Telecommunications: Annealed copper wire continues to be utilized in telecommunications networks, although fiber optics are increasingly common.

The ability to easily bend and shape annealed copper wire without breaking is essential for connecting various electrical components and facilitating complex wiring configurations.

Annealed Wire in Spring Manufacturing: Providing Resilience and Flexibility

High-carbon steel annealed wire is a cornerstone material in the spring manufacturing industry. The annealing process significantly enhances the wire’s elasticity and fatigue resistance, making it perfect for creating springs of all shapes and sizes. These springs are found in countless applications, including:

- Automotive components: Suspension systems, engine parts, and other automotive components rely heavily on annealed steel springs for their shock absorption and resilience.

- Household appliances: From the springs in your washing machine to those in your retractable clothesline, annealed wire springs are ubiquitous in everyday devices.

- Medical devices: Precision springs made from annealed wire are crucial components in various medical instruments and devices.

The ability of annealed steel wire to withstand repeated compression and extension cycles without losing its shape or breaking is critical for the reliable performance of these springs.

Beyond Springs and Electrical Wiring: Diverse Applications of Annealed Wire

The versatility of annealed wire extends far beyond electrical wiring and spring manufacturing. Its malleability and strength make it suitable for a wide range of other applications, such as:

- Wire forming and fabrication: Annealed wire is readily formed into intricate shapes and designs, making it popular in the manufacture of paper clips, wire mesh, and various other components.

- Welding applications: Certain types of annealed wire are used as filler materials in welding processes.

- Jewelry making: Annealed wire, particularly precious metals, is widely used in jewelry crafting due to its ease of manipulation and attractive finish.

- Musical instrument construction: Annealed wire is used in the construction of certain musical instruments, contributing to their tone and resonance.

The specific type of annealed wire used will depend on the application’s requirements for strength, ductility, and corrosion resistance.

Choosing the Right Annealed Wire: Considerations for Specific Applications

Selecting the appropriate type of annealed wire is crucial for ensuring the successful performance of the final product. Factors to consider include:

- Material: The choice of material (copper, steel, aluminum, etc.) depends on the application’s requirements for conductivity, strength, and corrosion resistance.

- Diameter: The wire diameter must be carefully chosen to meet the strength and flexibility requirements of the application.

- Annealing process: The specific annealing process used will affect the wire’s final properties. Understanding the different annealing techniques is crucial for selecting the optimal wire for a specific application.

- Surface finish: The surface finish of the wire can affect its performance and aesthetics. Options include bare wire, coated wire, and plated wire.

Consulting with a wire supplier is recommended to ensure the selection of the most suitable annealed wire for your specific application.

In conclusion, annealed wire’s unique properties and versatility make it an indispensable material in a wide array of industries. Understanding its characteristics and applications is key to leveraging its full potential in various manufacturing processes and technological advancements.