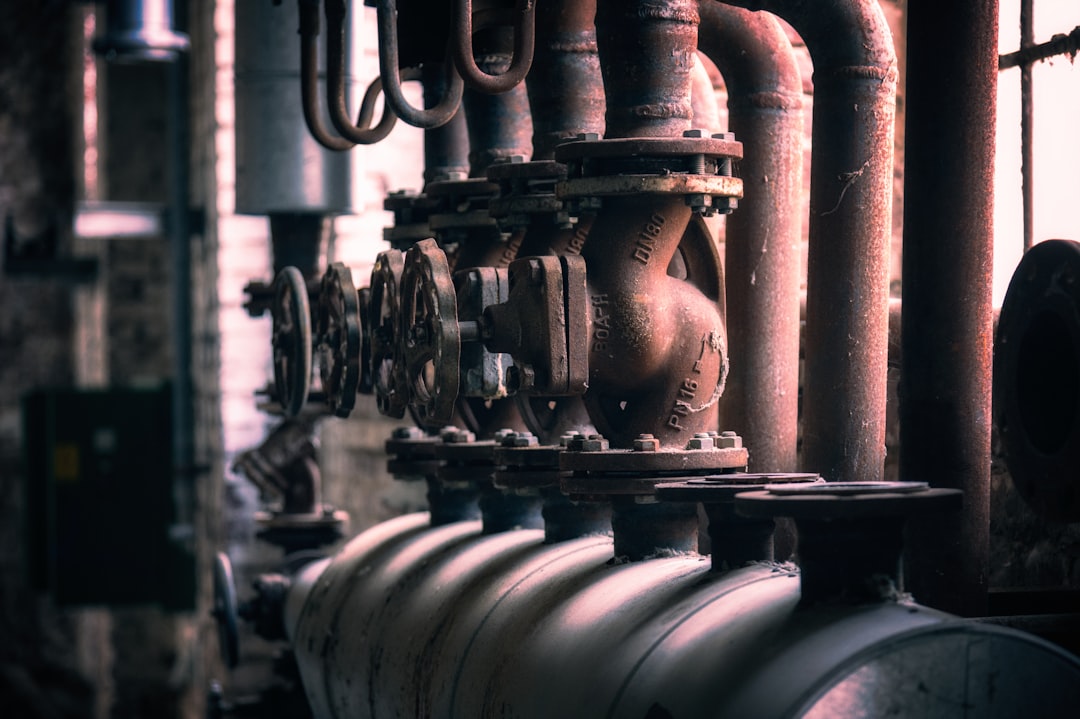

High-pressure piping systems are essential in various industries, from oil and gas to chemical processing and power generation. However, the inherent risks associated with high-pressure environments demand meticulous attention to safety. A single failure can have catastrophic consequences, leading to significant property damage, environmental contamination, and even loss of life. This comprehensive guide explores key aspects of high-pressure pipe safety, providing insights into best practices and preventative measures.

1. Material Selection: The Foundation of High-Pressure Pipe Safety

The choice of pipe material is paramount in ensuring the integrity of a high-pressure system. The material must possess sufficient strength and durability to withstand the operating pressures and temperatures. Common materials include carbon steel, stainless steel, and various alloys, each with its own strengths and limitations. Factors to consider include:

- Yield Strength: The material’s resistance to permanent deformation under stress.

- Tensile Strength: The maximum stress a material can withstand before fracturing.

- Corrosion Resistance: The material’s ability to resist degradation from the transported fluid or the environment.

- Temperature Resistance: The material’s ability to maintain its properties at elevated temperatures.

- Weldability: Ease of joining pipe sections for a seamless system.

Careful material selection, guided by industry standards and engineering calculations, is crucial to prevent failures due to material inadequacy.

2. Pressure Testing: Verifying System Integrity

Before a high-pressure piping system is put into operation, rigorous pressure testing is essential to verify its integrity. This involves subjecting the system to pressures exceeding the maximum operating pressure to identify any weaknesses or leaks. Hydrostatic testing, using water, is a common method, offering a relatively safe and cost-effective approach. Pneumatic testing, using compressed air or gas, is also used but requires stricter safety protocols due to the potential for explosive energy release.

The pressure test must be conducted according to established procedures, with careful monitoring of pressure and system behavior. Any leaks or deformations must be addressed before the system is deemed safe for operation. Detailed documentation of the testing process is crucial for future reference and regulatory compliance.

3. Regular Inspection and Maintenance: Preventing Catastrophic Failures

Regular inspection and maintenance are vital for maintaining the safety and longevity of high-pressure piping systems. A preventative maintenance program should include:

- Visual Inspections: Regularly checking for signs of corrosion, erosion, leaks, or damage.

- Non-Destructive Testing (NDT): Employing techniques like ultrasonic testing, radiographic testing, or magnetic particle inspection to detect internal flaws.

- Pressure Monitoring: Continuously monitoring system pressure to identify any deviations from normal operating parameters.

- Leak Detection: Implementing leak detection systems to quickly identify and address leaks.

- Scheduled Repairs and Replacements: Promptly addressing any identified issues, including repairs or component replacements.

A well-defined inspection and maintenance schedule, tailored to the specific system and operating conditions, is essential for preventing catastrophic failures.

4. Emergency Procedures: Responding to High-Pressure Incidents

Despite the best preventative measures, accidents can still occur. Having well-defined emergency procedures in place is crucial for minimizing the impact of high-pressure incidents. These procedures should cover:

- Emergency Shutdown Procedures: Quickly and safely shutting down the system in case of a failure.

- Emergency Response Team: A dedicated team trained to handle high-pressure incidents, equipped with appropriate safety gear and equipment.

- Evacuation Procedures: Safe and efficient evacuation of personnel from the affected area.

- Containment Procedures: Containing any released fluids or gases to minimize environmental impact.

- Communication Procedures: Establishing clear communication channels to coordinate emergency response efforts.

Regular drills and training are essential to ensure that personnel are familiar with and capable of executing emergency procedures effectively.

5. Regulatory Compliance and Industry Standards: Adhering to Best Practices

High-pressure piping systems are subject to stringent regulations and industry standards designed to ensure safety. Adherence to these regulations is not only crucial for legal compliance but also for ensuring the safety of personnel and the environment. Key standards and regulations include those set by organizations such as ASME (American Society of Mechanical Engineers), API (American Petroleum Institute), and OSHA (Occupational Safety and Health Administration). Staying informed about these standards and ensuring compliance is paramount for responsible operation of high-pressure systems.

Regular audits and inspections by regulatory bodies help verify compliance and identify areas for improvement. Proactive engagement with regulatory authorities and industry best practices is essential for maintaining a safe and compliant high-pressure piping system.

By diligently adhering to these principles, industries can significantly reduce the risks associated with high-pressure piping systems, ensuring the safety of their workforce and the environment.

Tags: high-pressure pipe safety, pressure testing, pipe inspection, pipe maintenance, industrial safety