In a world where fire safety is paramount, fire-resistant steel stands as a crucial bulwark against the destructive power of flames. From skyscrapers to industrial plants, these specialized materials play a vital role in protecting lives and property. This comprehensive guide delves into the fascinating world of fire-resistant steel, exploring its properties, applications, and the ongoing innovations shaping its future.

Understanding the Properties of Fire-Resistant Steel

Fire-resistant steel isn’t simply steel that’s been treated to withstand high temperatures; it’s a carefully engineered material with specific properties designed to maintain its structural integrity under intense heat. These properties include:

- High-Temperature Strength: Fire-resistant steel retains significant strength even at elevated temperatures, preventing collapse or deformation during a fire.

- Creep Resistance: This refers to the material’s resistance to deformation under sustained high temperatures and loads. This is critical for ensuring long-term structural stability.

- Oxidation Resistance: Exposure to high temperatures can cause rapid oxidation (rusting), weakening the steel. Fire-resistant steels are formulated to minimize this oxidation process.

- Thermal Stability: These steels maintain their dimensional stability even when subjected to significant temperature fluctuations, preventing warping or buckling.

- Ductility: While strength is key, maintaining some ductility (ability to deform without breaking) is important to absorb some energy during a fire event, further enhancing safety.

Types of Fire-Resistant Steel: A Comparative Analysis

Several types of fire-resistant steel exist, each with its own unique composition and properties tailored to specific applications. These include:

- Stainless Steels: Certain grades of stainless steel exhibit inherent fire resistance due to their chromium content, which forms a protective oxide layer. These are often used in less demanding applications.

- High-Strength Low-Alloy Steels (HSLA): These steels offer a balance of high strength and good fire resistance, making them suitable for structural applications in buildings and bridges.

- Alloy Steels: These steels contain specific alloying elements like molybdenum, vanadium, and niobium to enhance their high-temperature strength and creep resistance. They are commonly used in high-risk environments.

- Heat-Resistant Steels: These are specifically designed for prolonged exposure to extreme temperatures, often found in industrial furnaces and power plants. While extremely heat-resistant, they may not always offer the same level of structural integrity under fire conditions as specifically fire-resistant steels.

The choice of steel type depends on factors such as the anticipated fire temperature, duration of exposure, and the required structural performance.

Applications of Fire-Resistant Steel: Protecting Lives and Property

The versatility of fire-resistant steel makes it indispensable in a wide range of applications where fire safety is critical:

- Structural Components in Buildings: Columns, beams, and other structural elements in high-rise buildings, hospitals, and other critical structures are often constructed from fire-resistant steel.

- Fire Doors and Walls: Fire-resistant steel forms the backbone of fire-rated doors and walls, creating crucial fire barriers within buildings.

- Industrial Applications: Fire-resistant steel is essential in industrial settings like refineries, power plants, and chemical processing facilities, where the risk of fire is inherently higher.

- Transportation: Certain components in vehicles, especially those designed for hazardous materials transport, utilize fire-resistant steel for enhanced safety.

- Offshore Platforms: The harsh marine environment and potential for fire make fire-resistant steel a critical material in offshore oil and gas platforms.

Testing and Certification of Fire-Resistant Steel

Rigorous testing is crucial to ensure that fire-resistant steel meets the required performance standards. These tests evaluate the material’s ability to withstand high temperatures and maintain its structural integrity. Common testing methods include:

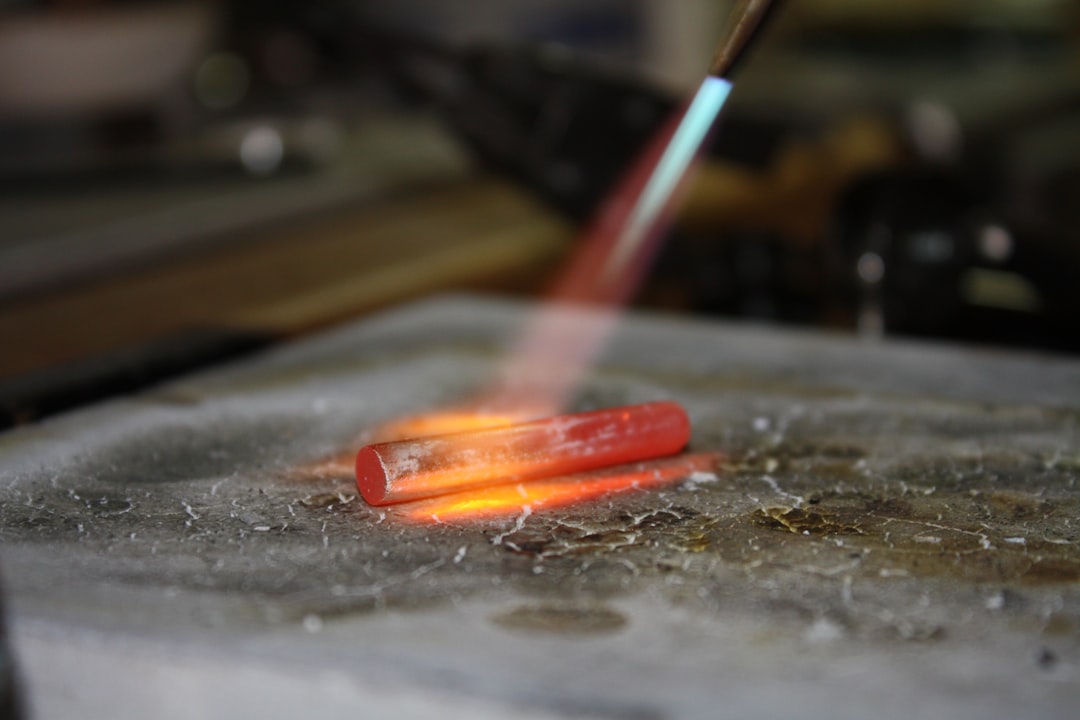

- Fire Resistance Tests: These tests subject samples of the steel to controlled fire conditions to assess their performance at different temperatures and durations.

- Mechanical Testing: Tests like tensile testing and impact testing are performed at elevated temperatures to determine the steel’s strength and ductility under fire conditions.

- Corrosion Testing: Tests evaluate the steel’s resistance to oxidation and corrosion at high temperatures.

Certification from recognized organizations ensures that the fire-resistant steel conforms to established standards and provides assurance of its quality and performance.

Future Innovations in Fire-Resistant Steel Technology

Research and development continue to push the boundaries of fire-resistant steel technology. Future innovations include:

- Advanced Alloying: Developing new alloy compositions to enhance high-temperature strength, creep resistance, and oxidation resistance.

- Improved Coating Technologies: Developing advanced coatings that further protect the steel from oxidation and enhance its fire resistance.

- Lightweight Fire-Resistant Steels: Research focuses on creating fire-resistant steels with reduced weight while maintaining their performance characteristics.

- Smart Materials: Incorporating sensors and other smart technologies to monitor the steel’s condition during a fire and provide real-time data on its performance.

These advancements promise to make fire-resistant steel even more effective in protecting lives and property from the devastating effects of fire.

Tags: fire resistant steel, fireproof steel, high temperature steel, structural steel, fire safety