body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

code { background-color: #f0f0f0; padding: 2px 4px; border-radius: 4px; }

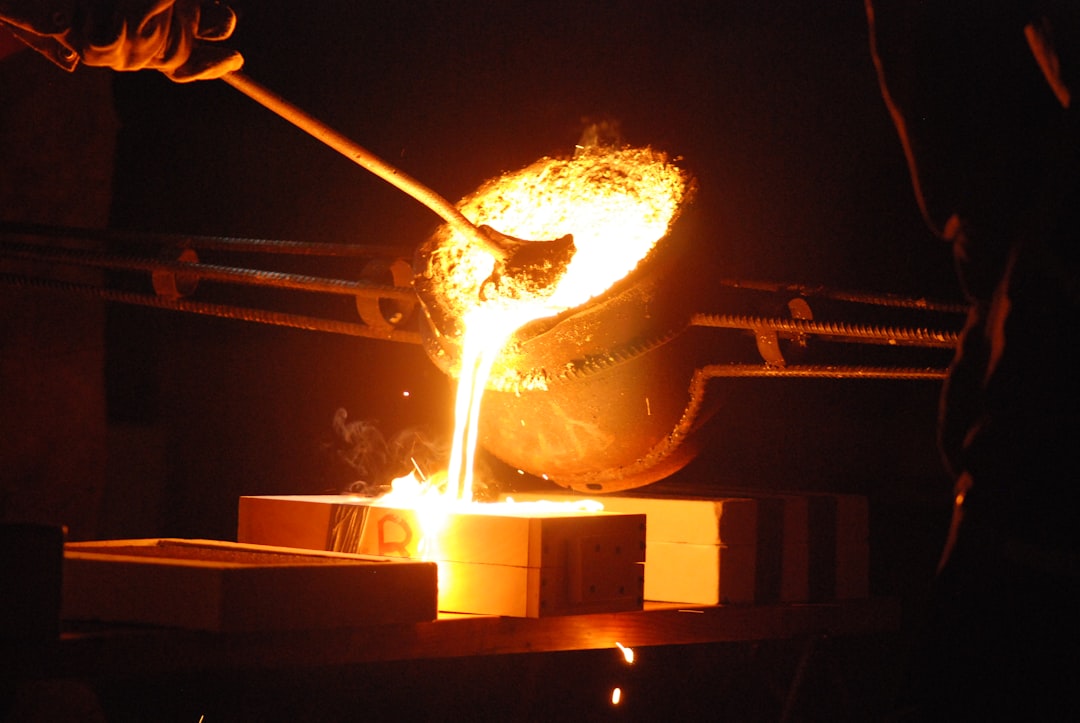

The production of high-quality steel relies heavily on rigorous quality control methods implemented throughout the entire process. From raw material selection to the finished product, meticulous testing and analysis are crucial to ensure the steel meets the required specifications and performs reliably in its intended application. This blog post delves into the key process steel quality control methods, providing a comprehensive understanding of how these techniques contribute to the creation of superior steel products.

1. Chemical Composition Analysis: The Foundation of Steel Quality

The chemical composition of steel is the cornerstone of its properties. Variations in the percentages of elements like carbon, manganese, silicon, phosphorus, sulfur, and alloying additions (chromium, nickel, molybdenum, etc.) significantly affect the steel’s strength, hardness, ductility, weldability, and corrosion resistance. Chemical analysis is performed at various stages of the steelmaking process, from the raw materials (iron ore, scrap) to the finished product. Techniques employed include:

- Spectroscopy (Optical Emission Spectrometry – OES): This rapid and accurate method uses the emission of light from excited atoms to determine the concentration of various elements. It’s widely used for routine quality control.

- Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES): Provides highly sensitive and precise elemental analysis, particularly useful for trace element determination.

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS): Offers even higher sensitivity than ICP-AES, ideal for detecting ultratrace elements.

- Wet Chemical Analysis: Traditional methods like titration and gravimetric analysis are still used for specific applications and verification purposes.

Accurate chemical analysis ensures that the steel conforms to the specified chemical composition, guaranteeing consistent properties and performance.

2. Mechanical Testing: Evaluating Steel’s Strength and Ductility

Mechanical testing evaluates the steel’s physical properties, such as strength, ductility, toughness, and hardness. These tests provide crucial information about the steel’s ability to withstand various stresses and strains. Common mechanical tests include:

- Tensile Testing: Determines the ultimate tensile strength, yield strength, elongation, and reduction in area. This test provides a comprehensive assessment of the steel’s strength and ductility.

- Hardness Testing: Measures the resistance of the steel to indentation. Common methods include Brinell, Rockwell, and Vickers hardness tests. Hardness is a good indicator of strength and wear resistance.

- Impact Testing (Charpy and Izod): Evaluates the steel’s ability to absorb energy upon impact, crucial for determining its toughness and resistance to brittle fracture, especially at low temperatures.

- Fatigue Testing: Assesses the steel’s resistance to failure under cyclic loading, important for components subjected to repeated stresses.

- Creep Testing: Measures the deformation of steel under sustained stress at elevated temperatures, essential for high-temperature applications.

Mechanical testing ensures that the steel possesses the necessary strength and ductility for its intended application.

3. Non-Destructive Testing (NDT): Ensuring Internal Integrity

Non-destructive testing methods allow for the evaluation of steel components without causing damage. These techniques are vital for detecting internal flaws such as cracks, porosity, inclusions, and other defects that might compromise the steel’s integrity. Common NDT methods include:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws. It’s highly effective for detecting subsurface defects.

- Radiographic Testing (RT): Employs X-rays or gamma rays to create images of the internal structure of the steel, revealing internal flaws.

- Magnetic Particle Testing (MT): Detects surface and near-surface cracks in ferromagnetic materials. It involves applying a magnetic field and then sprinkling ferromagnetic particles onto the surface.

- Liquid Penetrant Testing (PT): Detects surface-breaking flaws by applying a dye penetrant that seeps into the cracks and is then revealed using a developer.

- Eddy Current Testing (ECT): Uses electromagnetic induction to detect surface and subsurface flaws in conductive materials.

NDT methods provide a crucial safeguard against the use of defective steel components.

4. Microstructure Analysis: Understanding the Steel’s Internal Structure

The microstructure of steel, the arrangement of its constituent phases (ferrite, pearlite, martensite, etc.), significantly influences its mechanical properties. Microstructure analysis involves examining the steel’s internal structure using microscopy techniques:

- Optical Microscopy: Provides visual information about the grain size, shape, and distribution of phases in the steel.

- Scanning Electron Microscopy (SEM): Offers higher magnification and resolution than optical microscopy, allowing for detailed examination of the microstructure.

- Transmission Electron Microscopy (TEM): Provides the highest resolution, enabling the study of individual atoms and crystal structures.

Understanding the microstructure helps to correlate the processing parameters with the final properties and ensures the steel meets the desired specifications.

5. Surface Inspection: Ensuring Flawless External Appearance

While internal integrity is paramount, the surface quality of steel is also crucial, especially for applications where aesthetics or surface finish are important. Surface inspection involves visual examination and measurements to detect surface defects such as:

- Scratches and gouges: These defects can weaken the steel and affect its appearance.

- Scale and oxidation: These can interfere with further processing or affect the final product’s appearance.

- Surface roughness: This impacts the final finish and can affect the performance of the steel in certain applications.

Surface inspection ensures that the steel meets the required surface finish specifications and is free from defects that could compromise its appearance or performance.

In conclusion, the implementation of comprehensive quality control methods throughout the steel production process is essential for delivering high-quality, reliable steel products. The combination of chemical analysis, mechanical testing, non-destructive testing, microstructure analysis, and surface inspection ensures that the steel meets the required specifications and performs reliably in its intended application.

SEO Tags: Steel quality control, steel testing methods, non-destructive testing steel, chemical analysis steel, mechanical properties steel