Cold drawn flat bars are a crucial component in numerous industries, offering superior precision and mechanical properties compared to other steel products. This comprehensive guide will delve into the intricacies of these versatile materials, exploring their manufacturing, characteristics, and applications.

The Cold Drawing Process: Precision Engineering at its Finest

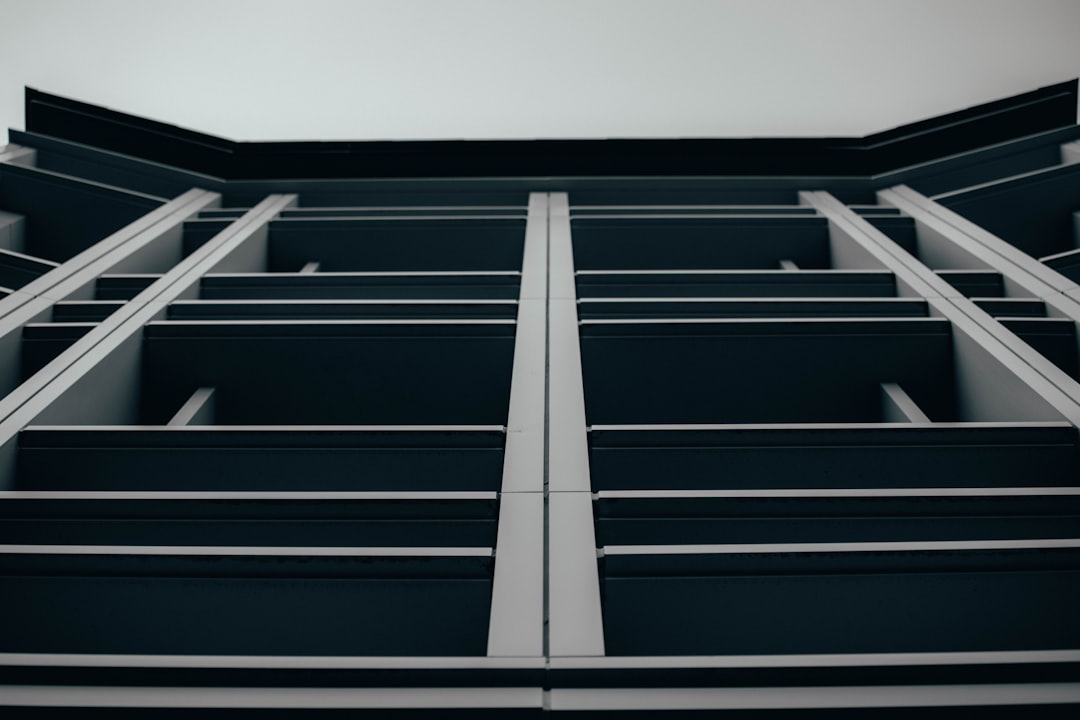

Cold drawing is a metal forming process that enhances the mechanical properties of steel bars. Unlike hot rolling, which involves heating the steel to high temperatures, cold drawing is performed at room temperature. A hot-rolled bar is first subjected to pickling to remove surface oxides and scale. Then, it’s drawn through a series of dies with progressively smaller cross-sectional areas. This process significantly reduces the bar’s cross-sectional area while simultaneously increasing its strength, surface finish, and dimensional accuracy. The cold working process introduces significant strain hardening, making the final product much stronger and harder than its hot-rolled counterpart.

The controlled deformation during cold drawing ensures exceptional dimensional tolerances, making cold drawn flat bars ideal for applications requiring precise measurements and tight specifications. The process also refines the grain structure of the steel, leading to improved surface finish and enhanced fatigue resistance.

Exceptional Mechanical Properties: Strength, Durability, and Precision

The cold drawing process dramatically alters the mechanical properties of the steel. Cold drawn flat bars exhibit significantly higher tensile strength, yield strength, and hardness compared to hot-rolled counterparts. This increased strength translates to greater durability and resistance to deformation under load. The process also improves the material’s fatigue resistance, meaning it can withstand repeated stress cycles without failure, a critical factor in many engineering applications.

The enhanced surface finish resulting from cold drawing minimizes stress concentrations, further contributing to improved fatigue life. The precise dimensions and consistent properties make cold drawn flat bars highly reliable and predictable in performance.

Diverse Applications Across Industries: From Automotive to Construction

The unique combination of strength, precision, and surface finish makes cold drawn flat bars highly versatile. They find applications in a wide range of industries, including:

- Automotive: Used in chassis components, suspension systems, and other critical parts requiring high strength and dimensional accuracy.

- Construction: Employed in structural components where high strength and durability are essential.

- Machinery and Equipment: Used in various machine parts, tools, and components requiring precise dimensions and high resistance to wear.

- Aerospace: Used in applications demanding high strength-to-weight ratios and exceptional fatigue resistance.

- Medical Devices: In applications requiring high precision and biocompatibility.

Advantages of Cold Drawn Flat Bars: Why Choose This Material?

Several key advantages distinguish cold drawn flat bars from other steel products:

- Superior Strength and Hardness: Significantly higher tensile strength, yield strength, and hardness compared to hot-rolled bars.

- Excellent Dimensional Accuracy: Precise dimensions and tolerances, minimizing machining requirements.

- Improved Surface Finish: Smoother surface reduces friction and enhances fatigue resistance.

- Enhanced Fatigue Resistance: Ability to withstand repeated stress cycles without failure.

- Cost-Effectiveness: Reduced machining needs can lead to overall cost savings.

Selecting the Right Cold Drawn Flat Bar: A Comprehensive Guide

Selecting the appropriate cold drawn flat bar requires careful consideration of several factors, including:

- Material Grade: Different grades of steel offer varying mechanical properties and corrosion resistance.

- Dimensions: Precise dimensions are crucial for proper fit and function.

- Surface Finish: Specific surface finishes may be required for certain applications.

- Mechanical Properties: Tensile strength, yield strength, and hardness should be chosen based on the application’s demands.

- Cost: Balancing performance requirements with budget constraints is essential.

Consulting with a materials specialist can ensure the selection of the optimal cold drawn flat bar for your specific needs.

Cold drawn flat bars represent a pinnacle of precision engineering, offering unparalleled strength, durability, and dimensional accuracy. Their versatility and superior properties make them an indispensable material across a wide spectrum of industries.

Tags: cold drawn flat bar, cold drawn steel, flat bar, steel bar, precision bar