body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

Steel, the backbone of modern construction and manufacturing, requires precise and efficient cutting methods. From the rudimentary techniques of the past to the sophisticated technologies of today, the evolution of steel cutting has been remarkable. This comprehensive guide explores the diverse range of steel cutting technologies, examining their processes, applications, advantages, and limitations.

1. The Legacy of Traditional Steel Cutting: Sawing and Shearing

Before the advent of advanced technologies, sawing and shearing were the primary methods for cutting steel. Sawing, utilizing various types of saws—from hand saws to power hacksaws and band saws—offered versatility but was relatively slow and prone to producing rough edges. The choice of saw blade (high-speed steel, carbide-tipped, or abrasive) significantly impacted cutting speed and surface finish. Shearing, on the other hand, involves applying a compressive force to cut the steel along a straight line. This method is efficient for straight cuts in thinner steel sheets but is limited in its ability to handle complex shapes or thicker materials. While less precise than modern methods, traditional techniques remain relevant in certain applications, particularly where cost-effectiveness is prioritized over extreme precision.

2. The Rise of Thermal Cutting: Oxy-Fuel and Plasma Cutting

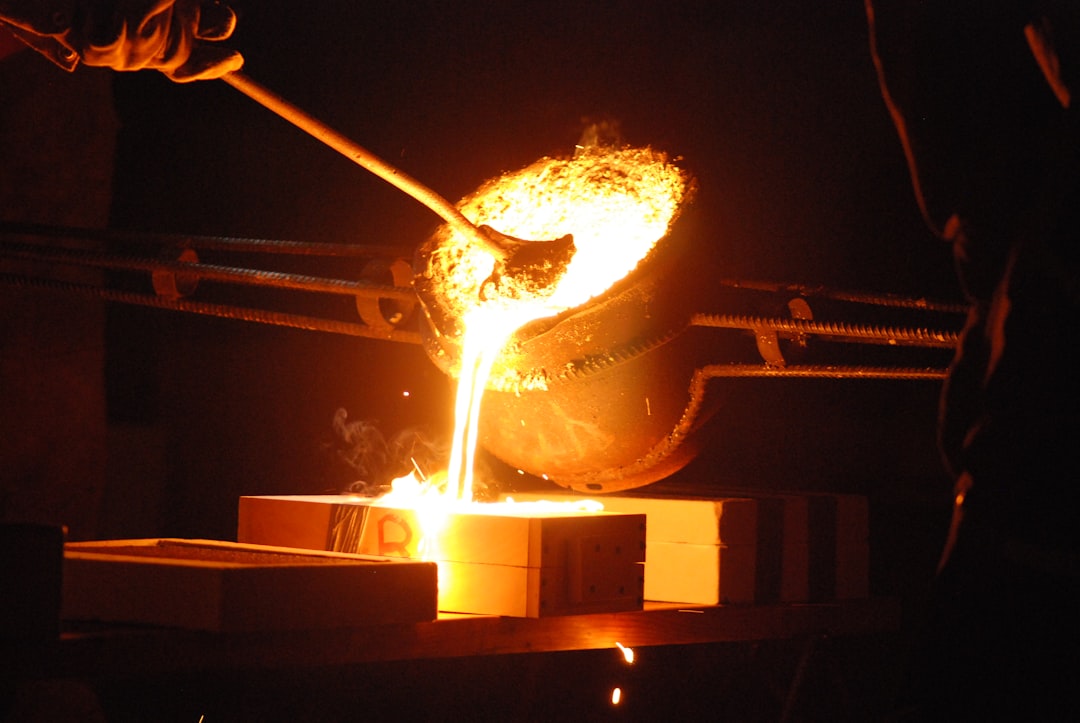

Oxy-fuel cutting, also known as flame cutting, utilizes a high-temperature flame produced by mixing oxygen and fuel gases (typically acetylene or propane). This intense heat melts and oxidizes the steel, allowing the oxygen jet to blow away the molten metal. Oxy-fuel cutting is relatively inexpensive and suitable for thicker steel plates, but it produces a wider kerf (cut width) and a rougher edge compared to other methods. Plasma cutting, a more advanced thermal process, uses a high-velocity jet of ionized gas (plasma) to cut the steel. Plasma cutting offers greater precision, faster cutting speeds, and a narrower kerf than oxy-fuel cutting. It’s effective on a wider range of steel thicknesses and can handle more intricate shapes. However, it requires more sophisticated equipment and is generally more expensive.

3. Precision Meets Speed: Laser Cutting of Steel

Laser cutting has revolutionized steel cutting, offering unparalleled precision and speed. A high-powered laser beam melts and vaporizes the steel, producing incredibly accurate cuts with minimal heat-affected zones. Laser cutting excels in creating intricate designs, fine details, and complex geometries. Different laser types (CO2 and fiber lasers) are employed depending on the material thickness and desired cutting quality. While laser cutting is more expensive than some other methods, its speed, precision, and ability to handle a wide range of steel grades make it ideal for high-volume production and intricate components.

4. Waterjet Cutting: A Gentle Giant for Precise Steel Cutting

Waterjet cutting utilizes a high-pressure jet of water, often mixed with an abrasive material like garnet, to cut steel. This method is remarkably versatile, capable of cutting a wide range of materials, including various steel grades, without the heat distortion associated with thermal cutting. Waterjet cutting offers excellent precision and can handle intricate shapes and delicate materials. It’s particularly suitable for cutting thicker steel plates where other methods might be less effective. However, it is generally slower than laser or plasma cutting.

5. Choosing the Right Steel Cutting Technology: Factors to Consider

Selecting the optimal steel cutting technology depends on several crucial factors: Material thickness: Thicker steel generally requires thermal cutting or waterjet cutting. Cut quality and precision: Laser cutting offers the highest precision, while sawing produces the roughest edges. Cutting speed: Laser and plasma cutting are generally faster than other methods. Cost: Traditional methods are often the most cost-effective, while laser cutting is typically the most expensive. Complexity of the design: Laser and waterjet cutting excel at handling complex shapes. Careful consideration of these factors ensures the selection of the most efficient and suitable steel cutting technology for the specific application.

The continuous advancements in steel cutting technologies promise even greater precision, speed, and efficiency in the future. As materials science and engineering progress, we can expect to see further innovations in this crucial area of manufacturing and construction.

SEO Keywords:

Steel cutting, laser cutting steel, plasma cutting, oxy-fuel cutting, waterjet cutting, steel fabrication