In the construction and manufacturing industries, the integrity of piping systems is paramount. From transporting crucial fluids in power plants to ensuring safe water distribution in cities, pipes are essential components demanding unwavering quality. This blog post delves into the comprehensive quality control systems implemented throughout the pipe manufacturing process, ensuring the delivery of reliable and durable products.

1. Raw Material Inspection: The Foundation of Quality

The journey towards a high-quality pipe begins long before the manufacturing process. Rigorous inspection of raw materials is the cornerstone of any effective quality control system. This involves meticulously examining the chemical composition, mechanical properties, and physical characteristics of the incoming materials. For steel pipes, this might include checking for the precise carbon content, tensile strength, yield strength, and elongation. For plastic pipes, the focus shifts to polymer type, molecular weight distribution, and additives. Non-destructive testing (NDT) methods like ultrasonic testing or magnetic particle inspection might be employed to detect internal flaws or surface imperfections in the raw materials before they even enter the production line. Detailed documentation and traceability are crucial at this stage, allowing for the identification of any batch of raw materials that might later be linked to a quality issue.

2. In-Process Control: Monitoring Each Stage of Production

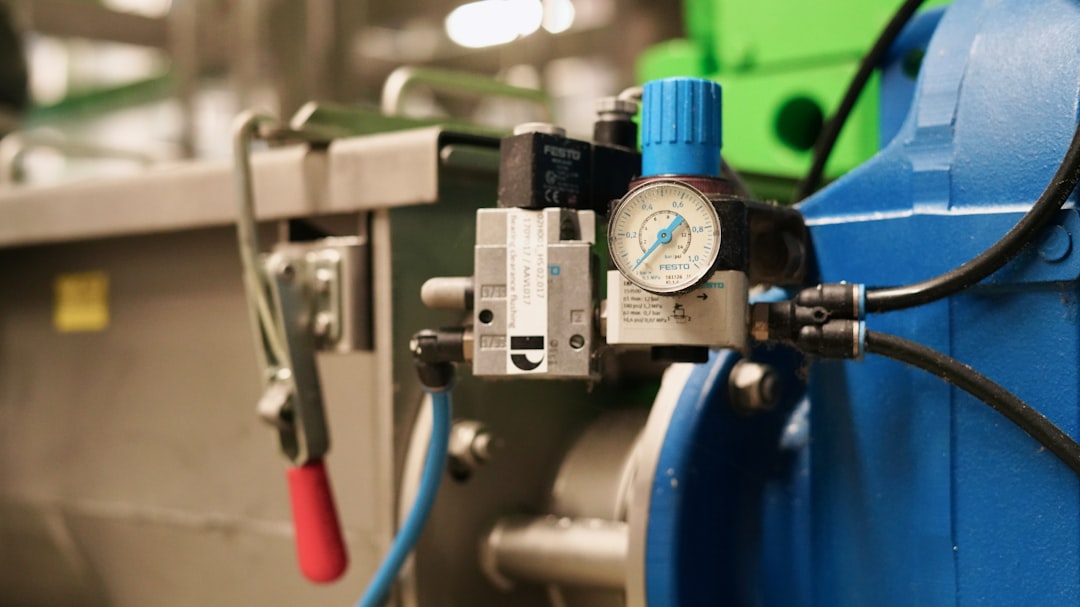

Maintaining consistent quality requires vigilant monitoring throughout the entire manufacturing process. In-process control involves regular inspections and testing at various stages of pipe production. This includes checking the dimensions of the pipe during forming, ensuring the correct wall thickness and diameter are maintained. For welded pipes, the welding process itself is subject to stringent quality checks, including visual inspection, radiographic testing (RT), and ultrasonic testing (UT) to detect any welding defects like porosity, cracks, or incomplete fusion. The heat treatment process, crucial for enhancing the mechanical properties of the pipe, is also carefully monitored and controlled to ensure the desired metallurgical structure is achieved. Data logging and statistical process control (SPC) techniques are often used to track key parameters and identify potential deviations from the desired specifications.

3. Dimensional Accuracy: Ensuring Precision and Conformity

Dimensional accuracy is a critical aspect of pipe quality. Pipes must meet precise specifications for diameter, wall thickness, length, and straightness to ensure proper fitting and functionality within the intended piping system. This requires the use of high-precision measuring instruments, such as calipers, micrometers, and laser scanners. Regular calibration of these instruments is crucial to maintain accuracy. Any deviations from the specified dimensions can lead to leakage, reduced strength, or incompatibility with connecting fittings. Automated measuring systems are increasingly used in modern pipe manufacturing facilities to provide real-time feedback and ensure consistent dimensional accuracy throughout the production process. These systems often integrate with the overall quality control system, allowing for immediate identification and correction of any dimensional discrepancies.

4. Testing Methodologies: Validating Performance and Durability

Beyond dimensional accuracy, various testing methodologies are employed to validate the performance and durability of the finished pipes. These tests are designed to evaluate the pipe’s resistance to internal pressure, external loads, and environmental factors. Hydrostatic testing is a common method used to assess the burst pressure and leakage resistance of the pipe under high internal pressure. This involves filling the pipe with water and subjecting it to increasing pressure until failure. Other tests might include impact testing, to assess the pipe’s resistance to sudden shocks, and fatigue testing, to determine its ability to withstand repeated stress cycles. The specific testing methodologies employed will depend on the pipe’s material, intended application, and relevant industry standards. Detailed test reports are essential for documenting the pipe’s performance characteristics and ensuring compliance with quality requirements.

5. Traceability and Documentation: Maintaining Accountability

A robust quality control system must include a comprehensive traceability system. This involves meticulously documenting every stage of the pipe’s lifecycle, from the sourcing of raw materials to the final delivery to the customer. Each pipe should be uniquely identifiable, allowing for the tracking of its entire manufacturing history. This is crucial for identifying the source of any quality issues that might arise and for ensuring accountability throughout the supply chain. Detailed records should be maintained for all inspections, tests, and manufacturing processes. This documentation serves as evidence of compliance with relevant standards and regulations and can be vital in resolving disputes or conducting root cause analysis in case of failures.

Implementing a comprehensive pipe product quality control system is an investment that pays off in the long run. It ensures the delivery of high-quality, reliable pipes, minimizing the risk of failures, reducing maintenance costs, and ultimately protecting the safety and efficiency of the systems in which they are used. By adhering to rigorous standards and employing advanced testing methodologies, manufacturers can build a reputation for excellence and deliver products that meet the highest industry benchmarks.

SEO Tags:

- Pipe Quality Control

- Pipe Manufacturing Quality

- Pipeline Inspection

- Pipe Testing Methods

- Quality Control Systems