Twisted square wire, with its unique strength and aesthetic appeal, offers a surprising range of applications beyond its common industrial uses. Its distinctive square shape and twisted structure provide both structural integrity and a visually interesting texture, making it a popular choice for a variety of creative and practical projects. This comprehensive guide explores the diverse world of twisted square wire and its many uses.

Crafting and Jewelry Making: Unleashing Artistic Potential

The robust yet malleable nature of twisted square wire makes it an ideal material for crafting and jewelry making. Its textured surface adds depth and visual interest to designs, while its strength ensures durability. Artists and crafters utilize twisted square wire in numerous ways:

- Wire wrapping: Creating intricate designs around gemstones, beads, and other components.

- Sculpting: Forming three-dimensional structures and figures.

- Jewelry components: Constructing earrings, bracelets, necklaces, and pendants.

- Basket weaving (small scale): Creating miniature baskets or decorative elements.

- Adding texture to mixed media projects: Incorporating it into paintings, sculptures, or other art forms.

The variety of available gauges and metals (such as copper, aluminum, and steel) allows for customization based on the desired aesthetic and structural requirements. The unique square shape provides a strong foundation for intricate designs, preventing the wire from collapsing or losing its form.

Industrial Applications: Strength and Reliability in Action

Twisted square wire’s high tensile strength and resistance to deformation make it a crucial component in numerous industrial applications. Its robust construction ensures reliability and longevity in demanding environments. Some key industrial uses include:

- Reinforcement in concrete and composites: Providing structural integrity and preventing cracking.

- Binding and tying applications: Securing materials in various industrial processes.

- Manufacturing of springs and other mechanical components: Its unique shape contributes to its resilience and ability to withstand repeated stress.

- Construction of fencing and cages: Providing durable and secure enclosures.

- Support structures in electrical and electronic components: Offering stability and protection.

The choice of material – often galvanized steel for enhanced corrosion resistance – is critical in determining the suitability of twisted square wire for specific industrial applications. The precise gauge and twist also influence the wire’s overall strength and flexibility.

Agricultural Uses: Supporting Growth and Productivity

Twisted square wire finds its place in agriculture, primarily due to its strength and resistance to weathering. Its applications in this sector are mainly focused on support and containment:

- Trellising for climbing plants: Providing support for vines, beans, and other climbing crops.

- Construction of animal enclosures: Creating robust and durable fences for livestock.

- Support structures for greenhouses: Contributing to the overall strength and stability of the greenhouse framework.

- Creating wire cages for protecting plants: Shielding plants from pests and animals.

- Supporting heavy crops: Preventing damage from over-burdened branches or stems.

Galvanized twisted square wire is often preferred in agricultural settings due to its corrosion resistance, ensuring longevity even under exposure to the elements. The wire’s strength is vital in supporting the weight of growing plants and protecting them from external damage.

Automotive and Transportation Applications: Ensuring Safety and Durability

The automotive and transportation industries utilize twisted square wire for its durability and ability to withstand vibrations and shocks. While not as prevalent as other materials, its specific properties find niche applications:

- Reinforcement in certain vehicle components: Providing structural support in less critical areas.

- Use in specialized vehicle modifications: Enhancing strength and durability in custom builds or repairs.

- Manufacturing of certain transportation equipment parts: Contributing to the robust design of equipment used in logistics and transportation.

- Reinforcement in cargo securing systems: Enhancing the safety and security of transported goods.

The choice of material and gauge in automotive applications is determined by the specific needs of the component and the overall vehicle design. The inherent strength and resistance to fatigue make it a suitable material for certain critical applications.

Beyond the Basics: Exploring Unique and Emerging Uses

The versatility of twisted square wire extends beyond its traditional applications. Innovation and creativity are constantly uncovering new ways to utilize this material. Some emerging and unique uses include:

- 3D printing support structures: Providing temporary support during the 3D printing process.

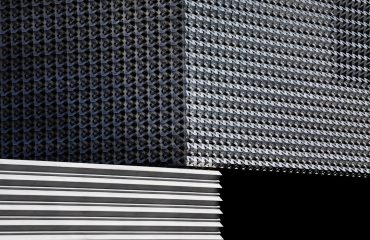

- Architectural elements in design: Adding unique textures and patterns to building facades or interior designs.

- Custom fabrication and prototyping: Creating unique prototypes and custom-designed components.

- Art installations and sculptures: Forming large-scale art pieces that combine strength and visual appeal.

The ongoing exploration of twisted square wire’s properties is likely to lead to even more innovative and unexpected applications in the future. Its inherent strength, malleability, and unique aesthetic qualities make it a valuable material for both established industries and emerging creative fields.

Tags: twisted square wire, wire uses, crafting wire, industrial wire, agricultural wire, jewelry making, metal wire