body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

Shot blasting is a powerful surface preparation technique used across numerous industries. This comprehensive guide will delve into the intricacies of this process, explaining its mechanics, applications, and safety considerations. Whether you’re a seasoned professional or simply curious about this industrial process, this article will provide you with a thorough understanding.

Understanding the Shot Blasting Process: A Step-by-Step Breakdown

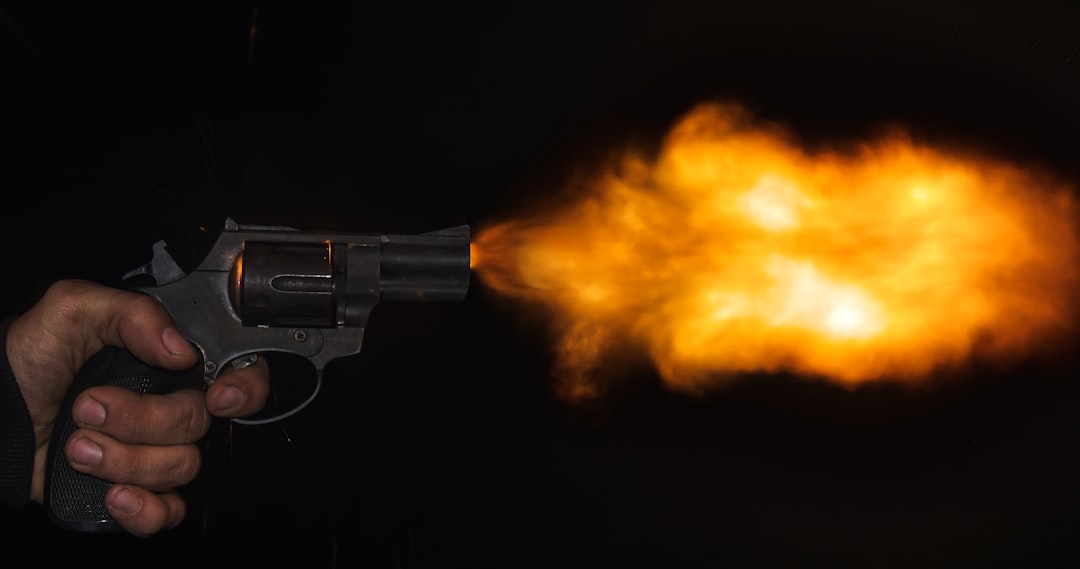

Shot blasting involves propelling a stream of abrasive media, typically small metallic or glass beads (the “shot”), at high velocity onto a workpiece’s surface. This high-impact process removes contaminants like rust, scale, paint, and other surface imperfections, leaving behind a clean, uniformly textured finish. The process typically involves several key steps:

- Workpiece Preparation: The item to be blasted needs initial preparation. This might involve masking off areas that shouldn’t be blasted or removing loose debris.

- Shot Selection: The type of abrasive media used depends on the material and surface finish required. Different materials, like steel shot, chilled iron shot, glass beads, or even walnut shells (for more delicate applications), offer varying levels of aggressiveness.

- Blasting Operation: The abrasive media is propelled by compressed air or centrifugal force within a shot blasting cabinet or machine. The intensity and duration of blasting are carefully controlled to achieve the desired surface profile.

- Post-Blasting Cleaning: After blasting, the workpiece is typically cleaned to remove any residual abrasive media. This might involve brushing, vacuuming, or compressed air.

- Inspection: A final inspection ensures the surface has achieved the desired cleanliness and texture.

Types of Shot Blasting Equipment: Choosing the Right Tool for the Job

The equipment used for shot blasting varies depending on the size and type of workpiece, the desired level of surface preparation, and the production volume. Common types include:

- Wheel Blast Machines: These use a rotating wheel to accelerate the abrasive media, offering high cleaning capacity for large workpieces.

- Air Blast Machines: These utilize compressed air to propel the abrasive media, providing more precise control and suitability for smaller or more delicate items.

- Cabinet Blast Machines: These enclosed units provide a contained environment for blasting, improving safety and containing dust.

- Automated Shot Blasting Systems: For high-volume production, automated systems offer efficiency and consistency.

Selecting the appropriate equipment is crucial for achieving optimal results and ensuring worker safety.

Applications of Shot Blasting Across Industries: A Wide Range of Uses

Shot blasting’s versatility makes it indispensable across a wide range of industries. Some key applications include:

- Automotive: Surface preparation of car bodies before painting, cleaning engine parts.

- Aerospace: Cleaning and preparing aircraft components for painting and other surface treatments.

- Construction: Cleaning and preparing steel structures before painting or coating.

- Manufacturing: Cleaning and deburring metal parts, improving surface adhesion for coatings.

- Marine: Cleaning and preparing ship hulls and other marine components.

The ability to remove rust, scale, and other surface imperfections makes shot blasting a critical step in many manufacturing processes.

Benefits of Shot Blasting: Enhanced Quality and Efficiency

Shot blasting offers numerous advantages over other surface preparation methods:

- Superior Cleaning: Removes contaminants more effectively than manual methods.

- Improved Surface Finish: Creates a uniform surface profile ideal for painting and coating.

- Enhanced Adhesion: Improves the adhesion of paint, coatings, and other surface treatments.

- Increased Durability: Extends the lifespan of treated components.

- Cost-Effective: Can be more efficient and cost-effective than manual cleaning methods, especially for large-scale operations.

These benefits contribute to improved product quality, increased production efficiency, and reduced overall costs.

Safety Precautions in Shot Blasting: Protecting Workers and the Environment

Shot blasting involves high-velocity projectiles and can pose significant safety risks if proper precautions aren’t taken. Essential safety measures include:

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, including respirators, safety glasses, hearing protection, and protective clothing.

- Containment Systems: Using enclosed blasting cabinets or systems helps to minimize dust and noise pollution.

- Regular Maintenance: Regular maintenance of equipment is crucial to prevent malfunctions and ensure safety.

- Training and Supervision: Workers should receive thorough training on safe operating procedures and be supervised by experienced personnel.

- Environmental Considerations: Proper disposal of spent abrasive media and dust collection are vital for environmental protection.

Adhering to strict safety protocols is paramount to ensuring a safe and healthy work environment.

Shot blasting is a powerful and versatile surface preparation technique with wide-ranging applications across various industries. By understanding the process, equipment, safety precautions, and benefits, businesses can leverage its power to enhance product quality, improve efficiency, and ensure worker safety.

Tags: shot blasting, surface preparation, abrasive blasting, industrial cleaning, metal finishing