The construction industry is undergoing a significant transformation, driven by the increasing demand for faster, more efficient, and sustainable building solutions. At the forefront of this revolution are prefabricated steel structures – a game-changer that’s reshaping the landscape of modern architecture and engineering. This comprehensive guide delves into the world of prefabricated steel structures, exploring their advantages, design process, diverse applications, sustainability aspects, and future trends.

The Unmatched Advantages of Prefabricated Steel Structures

Prefabricated steel structures offer a multitude of advantages over traditional construction methods. These benefits span across cost, time, quality, and sustainability, making them an attractive option for a wide range of projects. Key advantages include:

- Faster Construction Time: Components are fabricated off-site in a controlled environment, significantly reducing on-site construction time. This translates to faster project completion and quicker return on investment.

- Cost-Effectiveness: Prefabrication minimizes labor costs, material waste, and on-site delays, resulting in overall cost savings. The precision of factory fabrication also reduces the need for costly rework.

- Superior Quality and Precision: Factory fabrication ensures higher quality control and precision than on-site construction. This leads to fewer errors, improved structural integrity, and a longer lifespan for the building.

- Enhanced Durability and Strength: Steel is inherently strong and durable, resisting fire, pests, and extreme weather conditions better than many other materials. This translates to a longer lifespan and reduced maintenance costs.

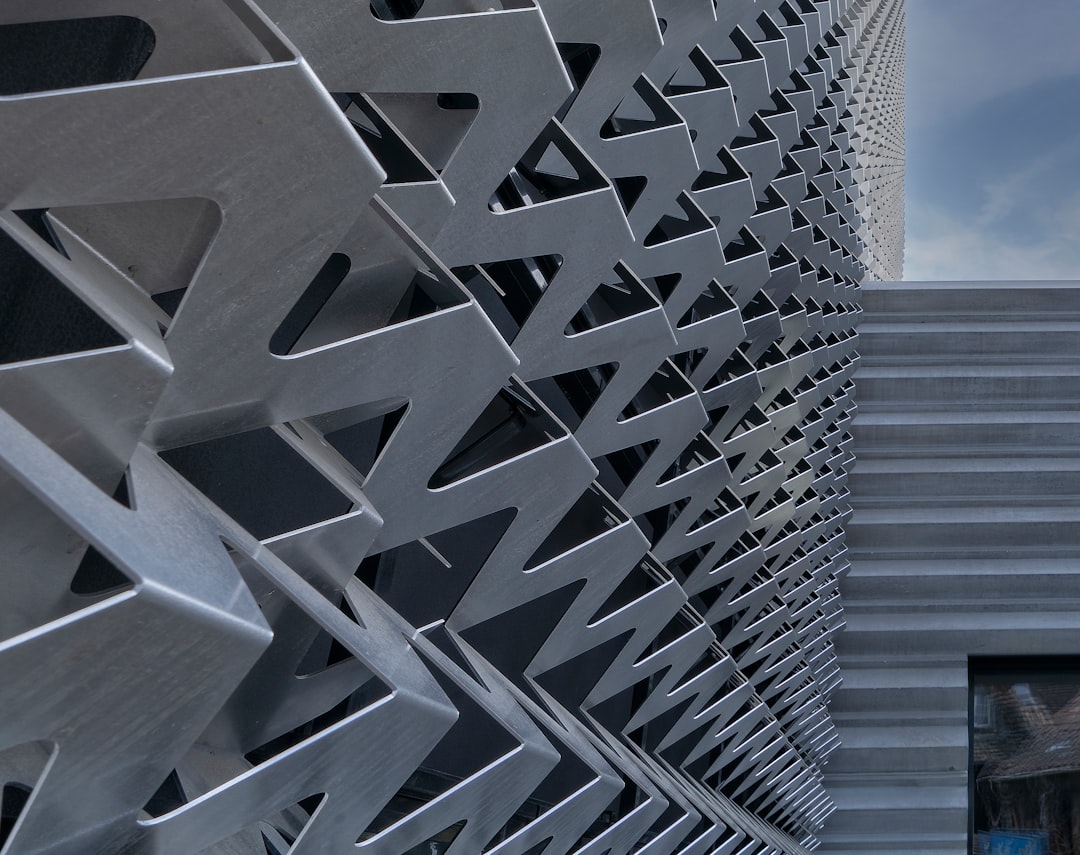

- Design Flexibility: Prefabricated steel structures can be designed and customized to meet a wide variety of architectural and functional requirements. Complex designs are achievable with precision and efficiency.

The Design and Fabrication Process: From Blueprint to Building

The design and fabrication process for prefabricated steel structures involves several key stages. It begins with detailed architectural and engineering designs, followed by precise fabrication in a controlled factory environment. The process typically includes:

- Detailed Design and Engineering: This phase involves creating precise 3D models and detailed engineering drawings, ensuring all components are accurately designed and compatible.

- Material Selection and Procurement: High-quality steel is selected based on project requirements, ensuring strength, durability, and resistance to corrosion.

- Off-site Fabrication: Steel components are precisely cut, shaped, and welded in a controlled factory setting, ensuring accuracy and quality control.

- Surface Treatment and Finishing: Components undergo surface treatments like galvanization or painting to protect against corrosion and enhance aesthetics.

- On-site Assembly: Prefabricated components are transported to the construction site and assembled quickly and efficiently, minimizing disruption.

Diverse Applications Across Industries: Where Steel Structures Shine

Prefabricated steel structures find applications in a vast array of industries and project types. Their versatility and adaptability make them suitable for:

- Industrial Buildings: Warehouses, factories, and manufacturing plants benefit from the strength, durability, and cost-effectiveness of steel structures.

- Commercial Buildings: Offices, retail spaces, and shopping malls can be constructed quickly and efficiently using prefabricated steel.

- Residential Buildings: From affordable housing to luxury homes, steel structures provide a strong, sustainable, and customizable base.

- Agricultural Structures: Barns, stables, and greenhouses can be built using prefabricated steel, offering durability and longevity.

- Infrastructure Projects: Bridges, railway stations, and other infrastructure projects can benefit from the speed and efficiency of prefabricated steel construction.

Sustainability and Environmental Impact: A Greener Approach to Building

Concerns about the environmental impact of construction are increasingly important. Prefabricated steel structures offer several advantages in terms of sustainability:

- Reduced Waste: Precise factory fabrication minimizes material waste compared to traditional construction methods.

- Recyclability: Steel is a highly recyclable material, reducing the environmental footprint of the building’s lifecycle.

- Energy Efficiency: Steel structures can be designed to incorporate energy-efficient features, reducing operational costs and environmental impact.

- Reduced Transportation Emissions: While transportation of materials is still a factor, the modular nature of prefabrication can often optimize transportation logistics, reducing overall emissions.

- Durability and Longevity: The long lifespan of steel structures reduces the need for frequent replacements, minimizing the overall environmental impact.

The Future of Prefabricated Steel Structures: Innovation and Trends

The future of prefabricated steel structures is bright, with ongoing innovations and advancements pushing the boundaries of design and construction. Emerging trends include:

- Increased Automation and Robotics: Automation in fabrication processes will further enhance precision, speed, and efficiency.

- Advanced Materials and Coatings: New steel alloys and coatings will improve durability, corrosion resistance, and fire protection.

- Integration of Smart Technologies: Smart sensors and building management systems will enhance energy efficiency and optimize building performance.

- Modular and Customizable Designs: Greater emphasis on modularity will allow for flexible and adaptable designs to meet diverse needs.

- Sustainable and Green Building Practices: Increased focus on sustainable materials, energy efficiency, and reduced carbon footprint will be key drivers of innovation.

In conclusion, prefabricated steel structures represent a significant advancement in the construction industry, offering a compelling combination of speed, cost-effectiveness, quality, and sustainability. Their versatility and adaptability make them a crucial element in shaping the built environment of the future.

SEO Tags: prefabricated steel structures, steel building construction, modular steel buildings, sustainable steel construction, industrial steel buildings