body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

img { max-width: 100%; height: auto; }

Fire-resistant steel plays a crucial role in protecting lives and property in countless applications, from skyscrapers and bridges to offshore platforms and industrial facilities. Understanding its properties, applications, and limitations is vital for ensuring structural integrity and safety in high-risk environments. This comprehensive guide explores the fascinating world of fire-resistant steel, delving into its intricacies and future potential.

Understanding the Properties of Fire-Resistant Steel

Unlike fireproof materials that completely prevent combustion, fire-resistant steel aims to maintain its structural integrity and load-bearing capacity for a specified duration under fire conditions. This is achieved through various mechanisms. The steel’s inherent strength and high melting point are crucial starting points. However, the real magic lies in the addition of alloying elements and specialized manufacturing processes. These elements, such as chromium, nickel, molybdenum, and silicon, significantly enhance the steel’s resistance to oxidation and heat degradation. The resulting steel exhibits improved high-temperature strength, reduced scaling (formation of oxide layers), and increased creep resistance (resistance to deformation under sustained stress at high temperatures). The specific composition and microstructure of the steel determine its fire resistance rating, which is often expressed in terms of the time it can withstand specific fire exposure conditions.

Types and Grades of Fire-Resistant Steel

Fire-resistant steel isn’t a single material but a family of alloys with varying compositions and properties. Common types include stainless steels (like 304 and 316 grades), high-strength low-alloy steels (HSLA), and specialized fire-resistant steels with proprietary compositions. The choice of grade depends on the specific application and the required fire resistance rating. For instance, stainless steels offer excellent corrosion resistance along with decent fire resistance, making them suitable for applications exposed to both fire and harsh environments. HSLA steels provide a balance between strength and fire resistance, while specialized fire-resistant steels are engineered for extreme fire conditions and demanding performance requirements. Each grade is meticulously tested and certified to meet specific standards, ensuring consistent performance and reliability.

Applications of Fire-Resistant Steel in Construction and Industry

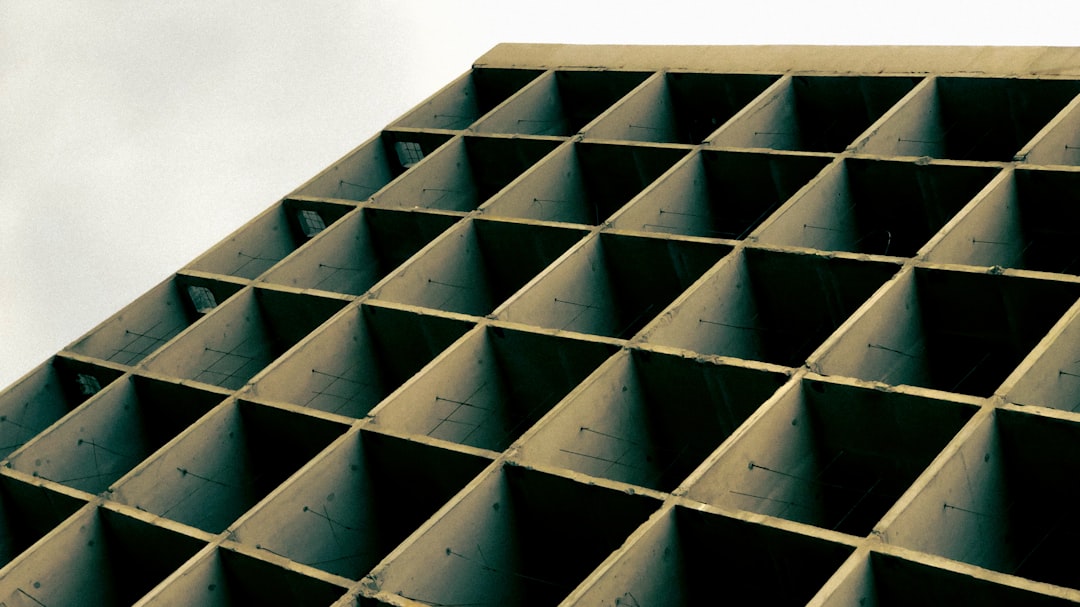

The applications of fire-resistant steel are vast and impactful. In construction, it forms the backbone of high-rise buildings, providing structural support in case of fire. It’s crucial in fire-rated walls, columns, beams, and floors, significantly enhancing the safety of occupants. Furthermore, fire-resistant steel is used extensively in bridges, tunnels, and other critical infrastructure projects, ensuring their structural integrity during fire events. The industrial sector relies heavily on fire-resistant steel in manufacturing plants, power stations, and offshore platforms, safeguarding equipment and personnel from fire hazards. Specific applications include protective casings for electrical components, fire-resistant doors and shutters, and structural elements in furnaces and other high-temperature environments.

Testing and Certification of Fire-Resistant Steel

Rigorous testing and certification are essential to ensure the performance and reliability of fire-resistant steel. Standardized tests, such as those defined by ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), evaluate the steel’s behavior under controlled fire conditions. These tests assess the material’s ability to maintain its structural integrity, strength, and stiffness at elevated temperatures for a specified duration. The tests typically involve exposing samples to standardized fire curves, simulating real-world fire scenarios. After exposure, the samples are evaluated for residual strength, deformation, and other relevant properties. Successful completion of these tests leads to certification, guaranteeing the steel’s compliance with specific fire resistance standards and enabling its use in critical applications.

Future Innovations and Trends in Fire-Resistant Steel

Research and development continue to push the boundaries of fire-resistant steel technology. Scientists and engineers are exploring new alloying elements and advanced manufacturing techniques to enhance the material’s performance and durability. The focus is on developing lighter, stronger, and more cost-effective fire-resistant steels with improved high-temperature properties. Furthermore, research is underway to integrate smart sensors and monitoring systems into fire-resistant steel structures to provide real-time data on their condition during fire events. This data can be used to optimize fire suppression strategies and improve building safety. The use of advanced computational modeling and simulation techniques is also accelerating the design and development of innovative fire-resistant steel structures.

In conclusion, fire-resistant steel is a critical material ensuring safety in a wide array of applications. Its continued development and innovation will undoubtedly lead to safer and more resilient structures in the future.

SEO Tags:

- Fire-resistant steel

- Fireproof steel

- High-temperature steel

- Structural steel fire protection

- Fire safety materials