High-pressure systems are integral to numerous industries, from chemical processing and oil and gas to power generation and pharmaceuticals. While offering significant advantages in efficiency and productivity, they also present substantial safety risks. A catastrophic failure can lead to serious injuries, fatalities, environmental damage, and significant financial losses. This comprehensive guide explores crucial safety considerations throughout the lifecycle of a high-pressure system.

1. Design and Engineering for High-Pressure Safety

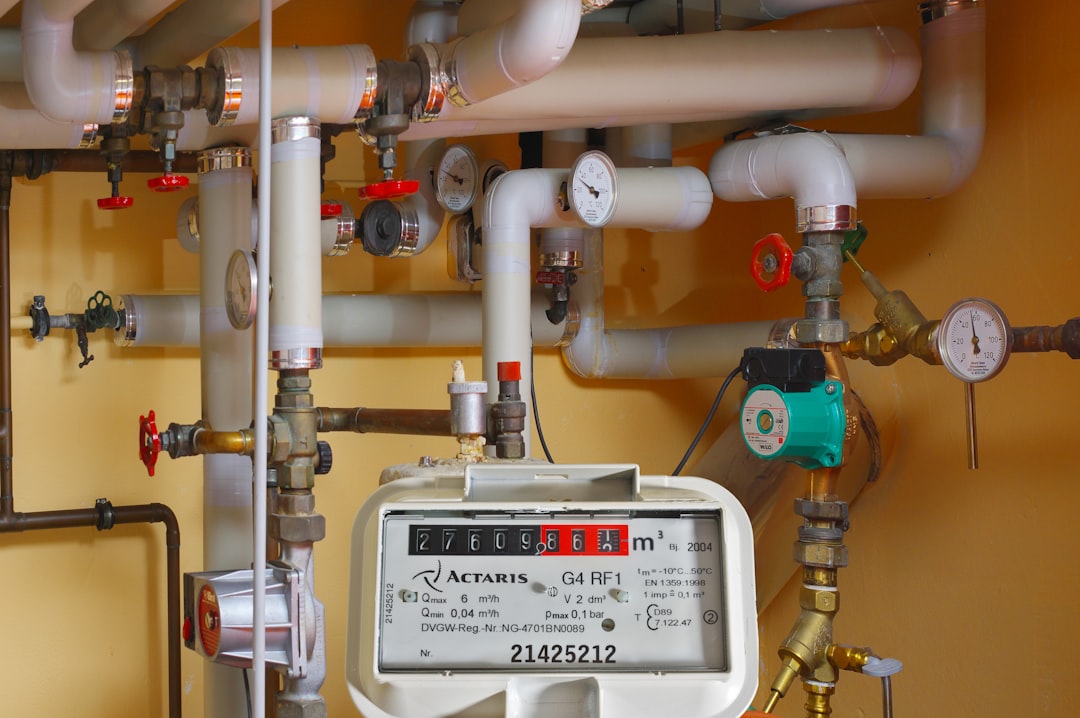

The foundation of a safe high-pressure system lies in its design and engineering. Careful consideration must be given to material selection, pressure vessel design, and component compatibility. Materials must possess sufficient strength and resistance to corrosion and fatigue under high-pressure conditions. Finite element analysis (FEA) is often employed to simulate stress and strain on components, ensuring they can withstand the anticipated pressures and temperatures. Proper design includes incorporating safety features like pressure relief valves, rupture disks, and pressure gauges. Detailed calculations and adherence to relevant industry codes and standards (e.g., ASME Section VIII, PED) are paramount. Regular review and updates to design specifications in response to operational experience and technological advancements are also critical.

2. Operational Procedures and Training for High-Pressure Systems

Even the best-designed high-pressure system requires meticulous operational procedures and well-trained personnel to function safely. Comprehensive operating manuals should detail startup and shutdown procedures, emergency response protocols, and routine inspections. Operators must receive thorough training on the system’s specific characteristics, potential hazards, and safe operating limits. This training should include hands-on experience with the equipment, as well as theoretical knowledge of pressure dynamics and safety regulations. Regular refresher training and competency assessments are essential to maintain operator proficiency and awareness of best practices. Clear communication channels and established reporting procedures for any anomalies or potential problems are also crucial.

3. Regular Maintenance and Inspection of High-Pressure Equipment

Preventive maintenance is the cornerstone of high-pressure system safety. A robust maintenance program should include regular inspections, testing, and repairs to prevent equipment failure. This includes visual inspections for leaks, corrosion, or damage, as well as non-destructive testing (NDT) techniques like ultrasonic testing or radiographic inspection to detect internal flaws. Pressure testing at regular intervals is critical to verify the integrity of the system. Accurate record-keeping of all maintenance activities is essential for tracking the system’s condition and ensuring compliance with regulations. A well-defined maintenance schedule, based on risk assessment and manufacturer recommendations, should be strictly followed.

4. Risk Assessment and Mitigation in High-Pressure Environments

A comprehensive risk assessment is essential to identify and mitigate potential hazards associated with high-pressure systems. This involves identifying potential failure modes, analyzing their likelihood and consequences, and implementing appropriate control measures. Hazard and Operability studies (HAZOP) are commonly used to systematically examine potential deviations from normal operating conditions. The risk assessment should consider both immediate and long-term risks, including the potential for environmental pollution or human error. Control measures may include engineering controls (e.g., improved design, safety interlocks), administrative controls (e.g., safety procedures, training), and personal protective equipment (PPE). Regular review and updating of the risk assessment are necessary to reflect changes in the system or operating conditions.

5. Emergency Response and Procedures for High-Pressure Incidents

Despite all precautions, incidents can still occur. Having a well-defined emergency response plan is crucial for minimizing the consequences of a high-pressure system failure. This plan should detail evacuation procedures, emergency shutdown procedures, and the roles and responsibilities of personnel in the event of an emergency. Emergency response teams should be adequately trained and equipped to handle various scenarios, including leaks, ruptures, and fires. Regular drills and simulations are essential to ensure the effectiveness of the emergency response plan. Communication protocols with emergency services and relevant authorities should be established and tested. Post-incident investigations should be conducted to identify root causes and prevent future occurrences.

By diligently addressing these safety considerations throughout the lifecycle of a high-pressure system, organizations can significantly reduce the risk of accidents and ensure the well-being of their employees and the environment. Remember that safety is not just a matter of compliance; it is a continuous process that requires commitment, vigilance, and a proactive approach to risk management.

SEO Tags:

- High-pressure systems safety

- Pressure vessel safety

- High-pressure system maintenance

- Industrial safety regulations

- High-pressure system risk assessment