Industrial machinery relies heavily on a robust and efficient piping system. From transporting fluids and gases to managing pressure and temperature, pipes are the circulatory system of many industrial processes. Understanding the intricacies of pipe usage is crucial for ensuring safety, optimizing performance, and maintaining the longevity of industrial equipment. This comprehensive guide delves into the key aspects of industrial piping, offering insights for engineers, technicians, and anyone interested in the inner workings of heavy machinery.

1. Material Selection: Choosing the Right Pipe for the Job

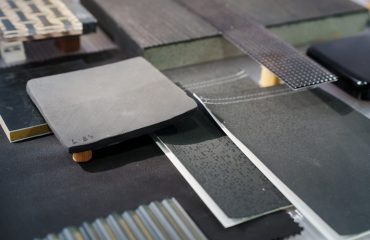

The choice of pipe material is paramount and depends heavily on the fluid being transported, the operating pressure and temperature, and the overall environment. Several common materials are used in industrial piping, each with its own advantages and limitations:

- Carbon Steel: A cost-effective and widely used material, suitable for a broad range of applications. However, it’s susceptible to corrosion, especially in aggressive environments. Protective coatings or specialized alloys are often necessary.

- Stainless Steel: Offers superior corrosion resistance compared to carbon steel, making it ideal for handling chemicals, acids, and other corrosive substances. Various grades of stainless steel exist, each with different properties and applications.

- Cast Iron: Used primarily for low-pressure applications due to its relatively lower strength. It’s resistant to corrosion but can be brittle.

- Plastic Pipes (PVC, HDPE, CPVC): Lightweight and corrosion-resistant, these are suitable for handling less aggressive fluids and lower pressures. They are often used in chemical processing and water treatment.

- Copper: Excellent corrosion resistance and thermal conductivity make copper pipes suitable for applications involving high temperatures and potable water.

Careful consideration of these factors is crucial to prevent leaks, failures, and potential safety hazards.

2. Pressure Ratings and Safety Considerations

Industrial pipes are designed to withstand specific pressure levels. The pressure rating, usually expressed in pounds per square inch (PSI) or bars, indicates the maximum allowable working pressure for a given pipe size and material. Operating above the rated pressure can lead to catastrophic failure, resulting in leaks, explosions, and serious injuries. Safety considerations include:

- Pressure Relief Valves: These valves automatically release excess pressure to prevent pipe rupture.

- Regular Inspections: Routine inspections and maintenance are essential to detect potential problems before they escalate.

- Proper Installation: Correct installation techniques are crucial to ensure the integrity of the piping system.

- Safety Training: Personnel working with high-pressure systems must receive adequate safety training.

- Emergency Shutdown Procedures: Clear and well-rehearsed emergency shutdown procedures are vital in case of leaks or other emergencies.

3. Common Applications of Industrial Piping in Machinery

Industrial piping systems are integral to a wide variety of machinery and processes:

- Chemical Processing: Transporting and handling various chemicals and reactants.

- Oil and Gas Refineries: Managing the flow of crude oil, refined products, and gases.

- Power Generation: Transporting steam, water, and other fluids in power plants.

- Food and Beverage Processing: Handling ingredients, liquids, and gases in food and beverage production.

- Pharmaceutical Manufacturing: Transporting sterile fluids and gases in pharmaceutical production.

- HVAC Systems: Distributing heated or cooled air in buildings and industrial facilities.

4. Maintenance and Inspection of Industrial Piping Systems

Regular maintenance is vital for ensuring the safety and efficiency of industrial piping systems. This includes:

- Visual Inspections: Regular visual inspections to detect corrosion, leaks, or damage.

- Pressure Testing: Periodic pressure testing to verify the integrity of the piping system.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or radiographic testing can detect internal flaws.

- Leak Detection: Implementing leak detection systems to quickly identify and address leaks.

- Cleaning and Flushing: Periodic cleaning and flushing to remove debris and buildup.

- Corrosion Prevention: Implementing corrosion prevention measures, such as coatings or cathodic protection.

5. Future Trends in Industrial Piping Technology

The industrial piping landscape is constantly evolving. Key trends include:

- Smart Piping Systems: Integration of sensors and data analytics to monitor pipe conditions and predict potential failures.

- Advanced Materials: Development of new materials with enhanced strength, corrosion resistance, and durability.

- Additive Manufacturing: 3D printing of custom pipes and fittings to reduce lead times and improve design flexibility.

- Improved Leak Detection Technologies: Development of more sensitive and accurate leak detection methods.

- Sustainable Practices: Increased focus on using eco-friendly materials and reducing waste in piping system manufacturing and maintenance.

In conclusion, understanding and effectively managing industrial piping systems is paramount for the safe and efficient operation of industrial machinery. By carefully considering material selection, pressure ratings, safety protocols, and maintenance practices, industries can minimize risks and maximize the lifespan and performance of their equipment.

Tags: Industrial Piping, Pipe Materials, Pressure Rating, Safety in Industry, Industrial Maintenance, Piping Systems