body { font-family: sans-serif; line-height: 1.6; }

h1, h2, h3 { color: #333; }

code { background-color: #f0f0f0; padding: 2px 4px; border-radius: 4px; }

High-strength, high-performance (HEA) profiles are revolutionizing structural engineering, enabling the construction of lighter, stronger, and more cost-effective heavy load structures. This comprehensive guide delves into the key aspects of utilizing HEA profiles, providing insights into their design, material selection, and practical applications.

Understanding High-Strength, High-Performance (HEA) Profiles

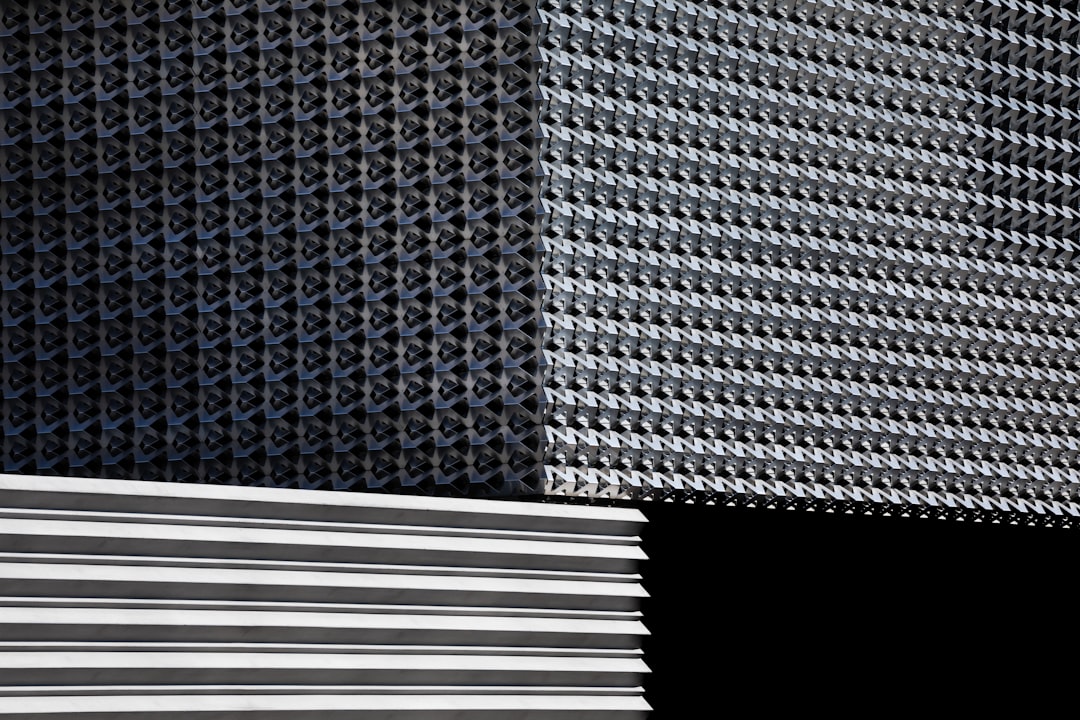

HEA profiles are advanced steel sections characterized by their significantly higher strength-to-weight ratio compared to traditional structural steel profiles. This superior performance stems from the use of high-strength steel grades and optimized section geometries. These optimized geometries often involve thinner flanges and webs, leading to weight reduction without compromising structural capacity. This efficiency translates to reduced material costs, lower transportation expenses, and faster construction times. Common HEA profiles include wide-flange beams (W-sections), hollow structural sections (HSS), and built-up sections. The specific profile chosen depends heavily on the application and the load conditions.

Material Selection for Optimal Performance

The choice of steel grade is crucial in determining the overall performance of an HEA profile. Higher strength grades, such as S355, S460, and even S690, offer increased yield strength and ultimate tensile strength, allowing for further weight reduction while maintaining structural integrity. However, higher strength grades often exhibit reduced ductility and weldability. Careful consideration must be given to these factors during the design phase. Factors like the intended application (e.g., bridges, skyscrapers, offshore structures), the anticipated load conditions (e.g., static, dynamic, seismic), and fabrication methods (e.g., welding, bolting) all influence the optimal steel grade selection. Detailed material testing and finite element analysis (FEA) are often employed to validate the chosen material’s suitability.

Design Considerations for Heavy Load Structures

Designing with HEA profiles necessitates a thorough understanding of advanced structural analysis techniques. Traditional design methods may not fully capture the complex stress distributions within these optimized sections. Finite element analysis (FEA) is frequently employed to accurately model the behavior of HEA profiles under various loading scenarios. FEA allows engineers to precisely determine stress concentrations, deflection, and buckling behavior. Furthermore, the slenderness of HEA profiles necessitates careful consideration of buckling and lateral-torsional buckling (LTB). Appropriate bracing and stiffening elements might be required to prevent these instability modes. Furthermore, the design must account for potential fabrication tolerances and residual stresses introduced during the manufacturing process.

Fabrication and Construction Techniques

The fabrication of structures using HEA profiles requires specialized techniques. Welding, for instance, requires precise control of the welding parameters to avoid cracking or other weld defects. The high strength of the steel necessitates the use of qualified welders and appropriate welding procedures. Bolting is another common connection method, and the selection of appropriate high-strength bolts and connection details is crucial for ensuring adequate joint strength and stiffness. The thinner sections of HEA profiles also require careful handling during transportation and erection to prevent damage. Proper site management and skilled labor are essential for successful construction projects employing HEA profiles.

Applications of HEA Profiles in Heavy Load Structures

HEA profiles find widespread applications in a diverse range of heavy load structures, including:

- Bridges: HEA profiles contribute to lighter and more efficient bridge designs, reducing material costs and improving overall structural performance.

- High-rise buildings: Their high strength-to-weight ratio enables the construction of taller buildings with reduced material consumption.

- Offshore structures: The superior strength and corrosion resistance of HEA profiles make them ideal for harsh marine environments.

- Industrial structures: HEA profiles are used in heavy industrial applications, such as factories and warehouses, where high load-bearing capacity is essential.

- Transportation infrastructure: From railway bridges to elevated roadways, HEA profiles offer significant advantages in terms of strength and weight efficiency.

The increasing demand for sustainable and efficient construction practices is driving the wider adoption of HEA profiles in heavy load structures worldwide.

Conclusion: The use of HEA profiles represents a significant advancement in structural engineering, offering substantial benefits in terms of strength, weight reduction, and cost-effectiveness. However, successful implementation necessitates a thorough understanding of design considerations, material selection, and fabrication techniques. By carefully considering these factors, engineers can leverage the full potential of HEA profiles to create innovative and sustainable heavy load structures.

Tags: HEA profiles, high-strength steel, heavy load structures, structural engineering, steel design