body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

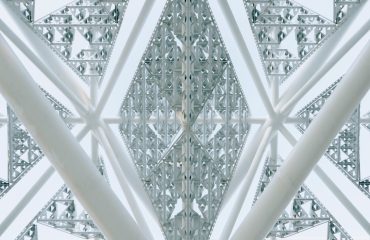

Scaffolding is an integral part of modern construction, providing temporary yet crucial support for workers and materials at various heights. At the heart of most scaffolding systems lie scaffolding pipes – the robust, versatile, and essential components that ensure the safety and efficiency of countless construction projects worldwide. This comprehensive guide delves into the multifaceted world of scaffolding pipes, exploring their types, applications, safety considerations, relevant regulations, and future trends.

Types of Scaffolding Pipes and Their Properties

Scaffolding pipes are predominantly made from high-strength steel, chosen for its durability, weldability, and resistance to bending and compression under heavy loads. Different types of steel pipes are used, each with specific properties catering to different project needs. These include:

- Black Steel Pipes: These are the most common type, offering a good balance of strength and affordability. They are often galvanized for added corrosion resistance.

- Galvanized Steel Pipes: The process of galvanization coats the pipes with zinc, providing superior protection against rust and extending their lifespan, particularly in outdoor or humid environments.

- Alloy Steel Pipes: Used in demanding situations requiring enhanced strength and resistance to extreme temperatures or corrosive chemicals.

- Aluminum Scaffolding Pipes: Lighter than steel, these are preferred in situations where weight is a significant factor, but they are generally less robust and more expensive.

The diameter and wall thickness of the pipes are crucial factors determining their load-bearing capacity. Standard sizes and specifications are often dictated by national and international building codes.

Applications of Scaffolding Pipes Across Diverse Construction Projects

The versatility of scaffolding pipes makes them indispensable across a wide range of construction projects, including:

- High-rise buildings: Providing access for workers during construction and maintenance.

- Bridge construction: Supporting workers and materials during the construction and repair of bridges.

- Industrial projects: Facilitating access to elevated equipment and structures in factories and refineries.

- Residential construction: Providing safe access for workers during the construction and renovation of houses and apartments.

- Maintenance and repair: Enabling safe access for repairs and maintenance work on existing buildings and structures.

The specific configuration of the scaffolding system – including the type of pipe, fittings, and the overall design – is tailored to the specific requirements of each project, ensuring stability and safety.

Ensuring Scaffolding Pipe Safety: Best Practices and Regulations

The safe use of scaffolding pipes is paramount. Strict adherence to safety regulations and best practices is essential to prevent accidents. Key aspects include:

- Regular inspections: Pipes should be inspected for damage, corrosion, or defects before each use. Damaged pipes must be immediately replaced.

- Proper erection and dismantling: Scaffolding should be erected and dismantled by trained and qualified personnel following established safety procedures.

- Load capacity: The scaffolding system must be designed and constructed to support the intended load without exceeding its capacity.

- Fall protection: Appropriate fall protection measures, such as guardrails, toe boards, and safety nets, should be implemented.

- Compliance with regulations: All scaffolding work must comply with relevant national and international safety standards and regulations.

Negligence in any of these areas can lead to serious accidents, highlighting the importance of rigorous safety protocols.

The Role of Fittings and Accessories in Scaffolding Pipe Systems

Scaffolding pipes are rarely used alone. A comprehensive scaffolding system relies heavily on a range of fittings and accessories, including:

- Couplers: Used to join pipes together, ensuring a secure and stable connection.

- Clamps: Used to secure horizontal and diagonal bracing members to vertical pipes.

- Base plates: Provide a stable base for the scaffolding system.

- Swivel couplers: Allow for adjustments and easier assembly.

- Toe boards and guardrails: Enhance safety by preventing falls.

The quality and compatibility of these fittings are just as crucial as the pipes themselves. Using substandard or incompatible components can compromise the structural integrity of the entire scaffolding system.

Future Trends in Scaffolding Pipe Technology and Usage

The scaffolding industry is constantly evolving, with new technologies and materials emerging to improve safety, efficiency, and sustainability. Some key trends include:

- Lightweight materials: Research into lighter yet stronger materials, such as advanced composites, could significantly reduce the weight and improve the handling of scaffolding systems.

- Improved fittings and connectors: Innovations in couplers and clamps aim to enhance ease of assembly, reduce installation time, and improve overall system stability.

- Modular scaffolding systems: Pre-fabricated and standardized components are simplifying the assembly and dismantling process, improving efficiency and reducing the risk of errors.

- Smart scaffolding technology: Integration of sensors and monitoring systems can provide real-time data on the structural integrity and stability of the scaffolding, allowing for proactive maintenance and preventing potential hazards.

- Sustainable materials: The use of recycled steel and exploring environmentally friendly alternatives are gaining traction as the construction industry strives for greater sustainability.

These advancements are poised to transform the way scaffolding is designed, constructed, and used in the years to come.

In conclusion, scaffolding pipes are fundamental to safe and efficient construction. Understanding their types, applications, safety implications, and future developments is crucial for all stakeholders involved in the construction industry. By prioritizing safety, adhering to regulations, and embracing innovation, we can continue to leverage the strength and versatility of scaffolding pipes to build a safer and more sustainable future.

SEO Tags:

- Scaffolding Pipes

- Construction Scaffolding

- Scaffolding Safety

- Steel Scaffolding Pipes

- Scaffolding Regulations