body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

display: block;

margin: 20px auto;

}

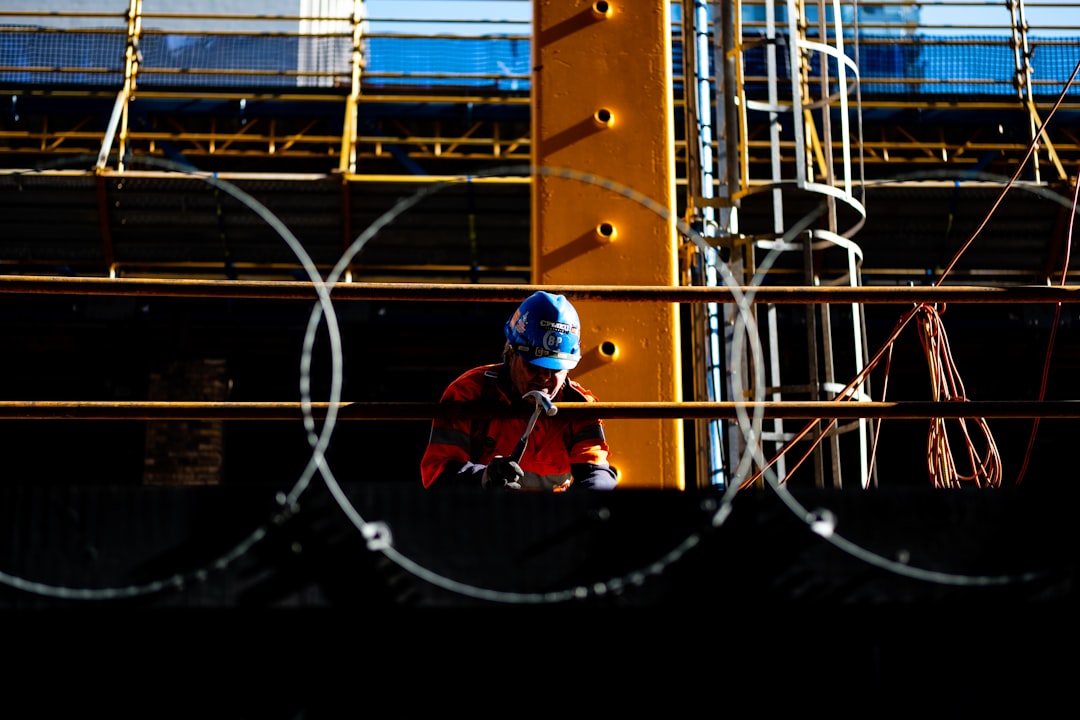

The oil and gas industry relies heavily on sophisticated well construction techniques. Two crucial components in this process are casing and tubing – steel pipes that play vital roles in ensuring safe, efficient, and productive hydrocarbon extraction. This comprehensive guide delves into the intricacies of casing and tubing, exploring their functions, types, materials, and installation.

The Fundamental Roles of Casing and Tubing

Casing and tubing, while both steel pipes, serve distinct purposes within a wellbore. Casing is the primary structural element, protecting the wellbore from collapse, preventing contamination of freshwater aquifers, and isolating different geological formations. It’s cemented in place to create a stable and sealed annulus (the space between the casing and the wellbore wall). Tubing, on the other hand, is the inner pipe through which hydrocarbons are extracted. It’s smaller in diameter than the casing and is suspended within the casing string. Think of it like this: the casing is the protective outer shell, and the tubing is the conduit for production.

Types and Grades of Casing and Tubing Steel

The selection of casing and tubing depends on various factors, including well depth, pressure, temperature, and the geological conditions encountered. Different grades of steel are used to meet these specific requirements. Commonly used casing grades include J-55, K-55, N-80, L-80, and P-110, with the designation indicating yield strength. Higher grades are employed for deeper and higher-pressure wells. Similarly, tubing grades vary, with common options including J-55, K-55, N-80, and L-80. The choice of steel grade is crucial for ensuring the structural integrity and longevity of the well.

Beyond the standard grades, specialized casing and tubing are available for specific applications. For instance, corrosion-resistant alloys might be used in environments prone to sulfide stress cracking or high levels of corrosive fluids. Similarly, high-strength low-alloy (HSLA) steels are chosen for their enhanced strength-to-weight ratio, particularly advantageous in deepwater applications.

The Casing Installation Process: A Step-by-Step Look

Casing installation is a complex process requiring precision and careful planning. It generally involves the following steps:

- Drilling the wellbore: The initial step involves drilling to the desired depth for the first casing string.

- Running the casing: The casing is lowered into the borehole using a specialized rig system.

- Cementing the casing: Cement slurry is pumped down the annulus between the casing and the wellbore wall. This creates a strong seal, preventing fluid migration and providing structural support.

- Displacing the cement: After the cement has set, the excess cement is displaced from the annulus.

- Testing the cement bond: Various tests are conducted to ensure the integrity of the cement bond between the casing and the formation.

- Repeating the process: For multi-stage wells, this process is repeated for subsequent casing strings, each designed for specific depth and pressure requirements.

Tubing Installation and Completion Operations

Once the casing is installed and cemented, the tubing string is run into the wellbore. This process involves carefully lowering the tubing string through the casing, connecting it to the production equipment at the surface. Tubing installation usually incorporates various downhole components, such as packers (to isolate different zones), perforating guns (to create pathways for hydrocarbon flow), and production packers (to isolate production zones).

The completion process, which follows tubing installation, involves connecting the tubing to surface equipment, including the Christmas tree (a valve assembly controlling well flow). This final stage ensures safe and efficient hydrocarbon production.

Challenges and Innovations in Casing and Tubing Technology

The oil and gas industry continually faces challenges related to casing and tubing, particularly in extreme environments. These include high temperatures, high pressures, and corrosive fluids. Innovations are constantly being developed to address these issues. These advancements include the development of advanced steel alloys with enhanced corrosion resistance and strength, improved cementing techniques, and the use of advanced monitoring systems to detect potential problems early on.

Furthermore, the industry is exploring alternative materials and designs for casing and tubing, including composite materials and advanced coatings, to enhance performance and reduce costs. These innovations are crucial for ensuring the safe and efficient extraction of hydrocarbons from increasingly challenging reservoirs.

Understanding the intricacies of casing and tubing is fundamental to comprehending the complexities of oil and gas well construction and production. The choice of materials, installation techniques, and ongoing maintenance are all critical for maximizing well productivity and minimizing environmental risks.

SEO-Friendly Tags:

- Oil and Gas Casing

- Oilfield Tubing

- Casing and Tubing Installation

- Well Completion

- Oil and Gas Well Construction