body {

font-family: sans-serif;

line-height: 1.6;

}

h1, h2, h3 {

color: #333;

}

img {

max-width: 100%;

height: auto;

}

Shot blasting is a surface treatment process that uses high-velocity projectiles to clean, deburr, and prepare various materials for further processing. This comprehensive guide will delve into the intricacies of this powerful technique, exploring its various applications and the crucial aspects of its implementation.

Understanding the Shot Blasting Process: A Step-by-Step Breakdown

The shot blasting process involves accelerating small, hard abrasive particles (the “shot”) at high speed towards a workpiece’s surface. This impact cleans the surface, removing contaminants like rust, scale, paint, and other surface imperfections. The process typically involves these key steps:

- Part Loading: The workpiece is securely positioned within the shot blasting cabinet or on a conveyor system designed for the specific size and shape of the component.

- Shot Acceleration: A spinning wheel (turbine) or compressed air propels the shot at high velocity.

- Impact and Cleaning: The high-velocity shot impacts the workpiece’s surface, dislodging contaminants and creating a slightly roughened profile.

- Shot Separation: After impacting the workpiece, the shot is separated from the cleaned part, usually through a series of screens and cyclones. This allows for shot reclamation and reuse.

- Part Unloading: The cleaned workpiece is then removed from the blasting cabinet or conveyor.

The entire process is typically automated to ensure consistent results and high throughput. The intensity and duration of the blasting process are carefully controlled to achieve the desired surface finish.

Types of Shot Blasting Equipment: Choosing the Right Tool for the Job

Various types of shot blasting equipment cater to different applications and workpiece sizes. The most common types include:

- Wheel Blast Machines: These machines use a rotating wheel to propel the shot, offering high cleaning power and are suitable for large-scale operations.

- Air Blast Machines: Compressed air propels the shot in these machines, offering more precise control and making them suitable for delicate workpieces.

- Cabinet Blast Machines: These enclosed units provide a controlled environment for blasting smaller parts, ensuring operator safety and consistent results.

- Automated Blast Systems: These systems integrate conveyors and robotic arms for high-volume, automated blasting processes, ideal for mass production.

- Portable Blast Machines: Smaller and more mobile units, ideal for on-site cleaning and smaller projects.

Selecting the appropriate equipment depends on factors like workpiece size, material, desired surface finish, and production volume.

Applications of Shot Blasting: A Wide Range of Industries Benefit

Shot blasting is a versatile surface treatment method with applications across numerous industries. Some key applications include:

- Metal Fabrication: Removing mill scale, rust, and other surface imperfections from steel, aluminum, and other metals before painting or further processing.

- Automotive Industry: Cleaning and preparing car bodies and parts for painting, ensuring a superior finish.

- Aerospace Industry: Cleaning and preparing aircraft components for inspection and painting, meeting stringent quality standards.

- Construction Industry: Cleaning and preparing steel structures before painting or coating, enhancing durability and corrosion resistance.

- Foundries: Cleaning castings to remove sand, scale, and other impurities, revealing the final shape and improving surface quality.

- Marine Industry: Cleaning and preparing ships and marine components to prevent corrosion and improve longevity.

The versatility of shot blasting makes it an essential process in ensuring high-quality surface finishes and extending the lifespan of various components.

Safety Precautions in Shot Blasting: Protecting Workers and Equipment

Shot blasting involves high-velocity projectiles and can pose significant safety risks if proper precautions aren’t taken. Essential safety measures include:

- Proper Personal Protective Equipment (PPE): This includes respirators to prevent inhalation of dust and abrasive particles, safety glasses to protect the eyes, hearing protection to reduce noise exposure, and protective clothing to prevent skin injuries.

- Enclosure and Containment: Using enclosed blasting cabinets and effective dust collection systems minimizes the spread of abrasive particles and dust.

- Regular Equipment Maintenance: Maintaining the shot blasting equipment in good working order helps prevent malfunctions and accidents.

- Proper Training and Supervision: Operators should receive adequate training on safe operating procedures and emergency response measures.

- Regular Safety Inspections: Regular inspections of the equipment and work area help identify and address potential hazards.

Adhering to strict safety protocols is crucial to prevent injuries and ensure a safe working environment.

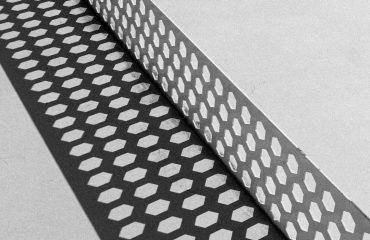

Shot Blasting Media: Selecting the Right Abrasive

The choice of shot blasting media significantly impacts the outcome of the process. Different media are available, each with specific properties and applications:

- Steel Shot: A common choice for cleaning and surface preparation, offering a balance of cleaning power and surface finish.

- Steel Grit: More angular than shot, providing more aggressive cleaning but potentially causing a rougher surface finish.

- Cast Iron Shot: Offers good cleaning power and is suitable for various applications.

- Glass Beads: A gentler abrasive, ideal for cleaning delicate surfaces without causing significant surface damage.

- Ceramic Media: Durable and chemically inert, suitable for cleaning sensitive materials.

The selection of the appropriate blasting media depends on factors such as the material of the workpiece, the level of cleaning required, and the desired surface finish.

Shot blasting is a powerful and versatile surface treatment process with numerous applications across various industries. By understanding the process, choosing the right equipment, and adhering to safety precautions, businesses can leverage shot blasting to improve product quality, enhance efficiency, and ensure worker safety.

Tags: Shot blasting, surface treatment, abrasive blasting, metal cleaning, surface preparation