Choosing the right steel for a specific application requires a thorough understanding of its properties. Two prominent types of stainless steel, ferritic and austenitic, offer distinct advantages and disadvantages. This comprehensive guide will explore the key differences between these two steel families, helping you make informed decisions for your projects.

1. Crystal Structure: The Foundation of Their Differences

The fundamental distinction between ferritic and austenitic stainless steels lies in their crystal structure. Ferritic stainless steels possess a body-centered cubic (BCC) crystal structure at room temperature. This structure is characterized by a single atom at the corners of a cube and one in the center. This arrangement results in a relatively simple and tightly packed structure. In contrast, austenitic stainless steels exhibit a face-centered cubic (FCC) crystal structure. This structure has atoms at each corner of the cube and one at the center of each face. The FCC structure is more densely packed than the BCC structure, leading to different mechanical and physical properties.

2. Composition: The Alloying Elements That Define Their Characteristics

The compositional differences between ferritic and austenitic steels significantly influence their properties. Ferritic steels primarily contain chromium (typically 10-30%) as the primary alloying element, responsible for their corrosion resistance. They may also contain small amounts of molybdenum, niobium, or titanium to further enhance corrosion resistance and strength. Austenitic steels, on the other hand, are characterized by high levels of chromium (16-26%) and nickel (6-22%). Nickel is crucial for stabilizing the austenitic FCC structure at room temperature. Molybdenum and manganese are also frequently added to improve corrosion resistance and mechanical properties.

3. Mechanical Properties: Strength, Ductility, and Formability

The differences in crystal structure and composition translate to distinct mechanical properties. Ferritic steels generally exhibit higher strength and hardness than austenitic steels, but they are significantly less ductile and formable. This means they are more prone to cracking during bending or shaping. Austenitic steels, due to their FCC structure, are renowned for their excellent ductility, formability, and toughness. They can be easily bent, drawn, and stamped into complex shapes without fracturing. However, they are generally less strong than ferritic steels.

4. Applications: Where Each Steel Shines

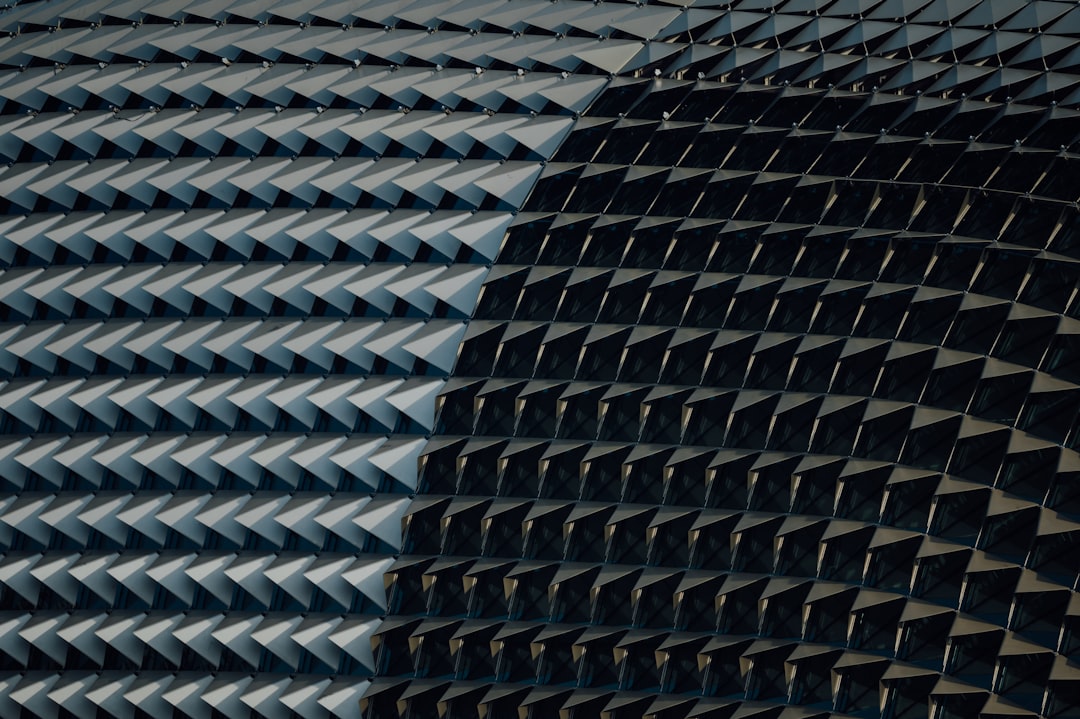

The unique properties of ferritic and austenitic steels dictate their suitability for various applications. Ferritic steels are often chosen for applications where high strength and good corrosion resistance are required, but high formability is less critical. Examples include automotive exhaust systems, chemical processing equipment, and certain types of kitchen appliances. Austenitic steels, with their superior formability and weldability, are preferred for applications demanding complex shapes and ease of fabrication. They are widely used in food processing equipment, medical devices, architectural cladding, and cryogenic applications.

5. Welding and Fabrication: Considerations for Manufacturing

Welding and fabrication techniques must be tailored to each steel type. Ferritic steels are generally more susceptible to cracking during welding due to their lower ductility. Special welding procedures, such as using low-heat input techniques and preheating, are often necessary to prevent cracking. Austenitic steels are known for their excellent weldability, making them easier to fabricate and join. However, austenitic steels are prone to sensitization, which reduces their corrosion resistance in certain environments. Proper post-weld heat treatment may be required to mitigate this issue.

In conclusion, the choice between ferritic and austenitic stainless steel depends heavily on the specific requirements of the application. Understanding the fundamental differences in their crystal structure, composition, mechanical properties, and fabrication characteristics is crucial for selecting the optimal material for your project.

SEO Tags:

- Ferritic Steel

- Austenitic Steel

- Stainless Steel Comparison

- Steel Properties

- Material Selection Guide