Electric Resistance Welded (ERW) pipes are a cornerstone of modern construction and industrial applications. Their efficient manufacturing process and versatile properties make them a cost-effective and reliable choice for a wide range of projects. This comprehensive guide delves into the world of ERW pipes, exploring their manufacturing, applications, advantages, limitations, and future prospects.

The ERW Pipe Manufacturing Process: A Detailed Look

The creation of ERW pipes begins with a steel strip, carefully coiled and fed into a forming mill. This mill shapes the strip into a cylindrical form, preparing it for the crucial welding stage. High-frequency electric current is then applied to the edges of the overlapping strip, heating them to the point of fusion. Simultaneously, pressure is applied to forge a seamless weld, creating a continuous pipe. This process is remarkably efficient, capable of producing long lengths of pipe with consistent dimensions and high-quality welds. Post-weld processes, including sizing, straightening, and inspection, ensure the final product meets stringent quality standards. The entire process is automated and highly controlled, minimizing human error and maximizing productivity. Different grades of steel can be used, influencing the pipe’s strength and suitability for specific applications. This flexibility is a key advantage of the ERW process.

Diverse Applications of ERW Pipes Across Industries

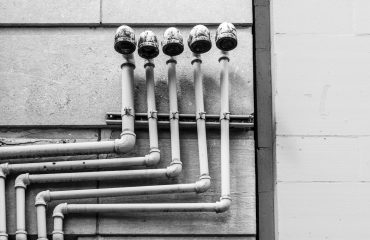

The strength, durability, and cost-effectiveness of ERW pipes make them suitable for a vast array of applications. In the construction industry, they are widely used for structural purposes, including scaffolding, building frameworks, and supporting infrastructure. Their ability to withstand significant stress and pressure makes them ideal for water and gas pipelines, ensuring the safe and efficient transportation of essential resources. The automotive industry also relies heavily on ERW pipes for chassis components, offering a balance of strength and lightweight design. Furthermore, ERW pipes find their place in agricultural irrigation systems, providing a robust and reliable solution for water distribution. The oil and gas industry utilizes ERW pipes in pipelines transporting crude oil and natural gas, showcasing their ability to handle high pressures and corrosive environments (depending on the chosen steel grade and protective coatings).

Advantages of ERW Pipes: Why Choose This Option?

Several factors contribute to the popularity of ERW pipes. Firstly, their cost-effectiveness is a significant advantage, often making them a more economical choice compared to other pipe manufacturing methods. The high-speed, automated production process contributes to this affordability. Secondly, ERW pipes offer excellent strength and durability, capable of withstanding significant pressure and stress. This makes them suitable for a wide range of demanding applications. Thirdly, the consistent dimensions produced during the manufacturing process ensure easy installation and precise fitting. Finally, ERW pipes are available in a wide range of sizes and specifications, allowing for flexibility in design and application. The ability to tailor the pipe’s properties through the selection of different steel grades further enhances their versatility.

Limitations of ERW Pipes: Understanding the Drawbacks

While ERW pipes offer many benefits, it’s essential to acknowledge their limitations. One key drawback is the potential for weld imperfections, although modern manufacturing processes have significantly minimized this risk. Thorough quality control measures are crucial to ensure the integrity of the welds. Furthermore, compared to seamless pipes, ERW pipes might exhibit slightly reduced ductility in some cases, impacting their ability to withstand bending stress. However, advancements in steel metallurgy and welding techniques are continuously improving the overall quality and performance of ERW pipes. The choice between ERW and seamless pipes ultimately depends on the specific application requirements and the acceptable trade-offs between cost, strength, and ductility.

The Future of ERW Pipes: Innovation and Advancements

The future of ERW pipes is bright, driven by ongoing innovations in manufacturing techniques and material science. Research is focused on improving weld quality, enhancing the strength and durability of the pipes, and exploring the use of advanced materials, such as high-strength low-alloy (HSLA) steels, to meet the demands of increasingly challenging applications. Furthermore, developments in automation and process optimization are expected to further enhance the efficiency and cost-effectiveness of ERW pipe production. The integration of smart manufacturing technologies and predictive maintenance strategies will likely lead to improvements in quality control and reduce downtime. The continued demand for robust and cost-effective piping solutions across various industries ensures that ERW pipes will remain a vital component of infrastructure and industrial processes for years to come.

Tags: ERW Pipes, Electric Resistance Welded Pipes, Steel Pipes, Pipe Applications, Construction Materials