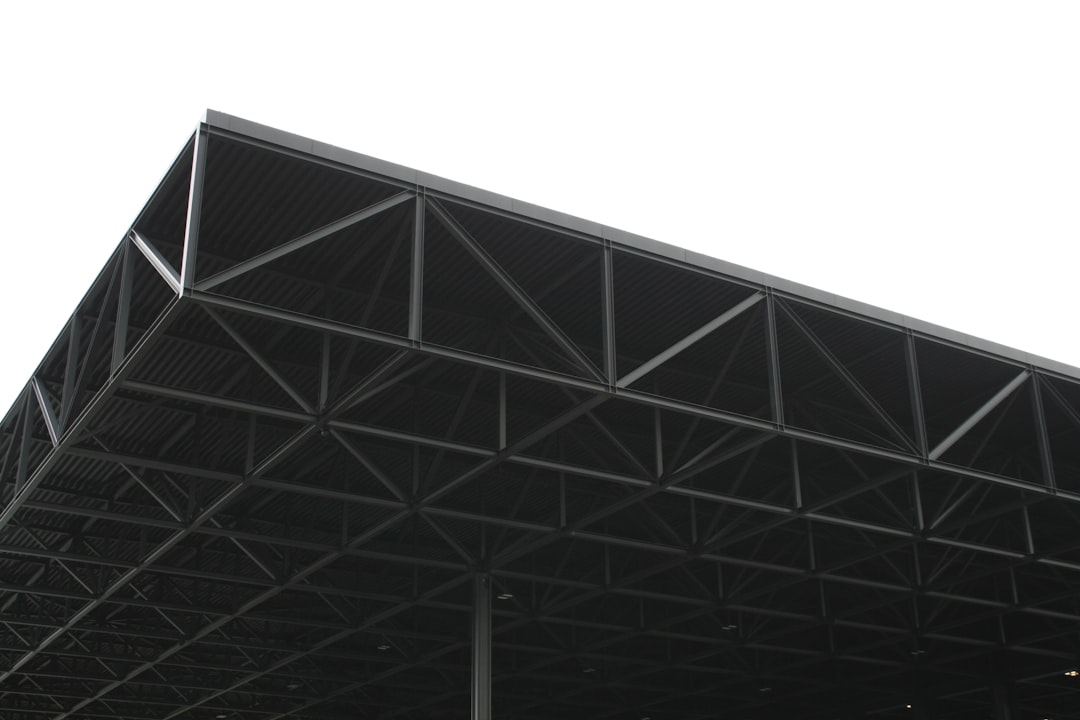

In today’s world, noise pollution is a significant concern, impacting productivity, health, and overall well-being. Effective sound control is crucial in various environments, from bustling offices to quiet residential spaces. Acoustic steel profile systems offer a robust and versatile solution for managing noise levels, providing superior sound insulation and creating quieter, more comfortable environments. This comprehensive guide explores the intricacies of these systems, delving into their design, installation, benefits, and applications.

Understanding the Mechanics of Acoustic Steel Profile Systems

Acoustic steel profile systems are engineered structures designed to minimize sound transmission. Unlike traditional methods relying solely on dense materials like concrete or drywall, these systems leverage the properties of steel profiles combined with specialized acoustic materials to achieve significant noise reduction. The core principle revolves around creating an air gap within the system, disrupting sound waves and reducing their energy before they can penetrate through. This air gap is often filled with sound-absorbing materials like mineral wool or fiberglass, further enhancing the system’s acoustic performance. The steel profiles themselves provide structural integrity and support for the entire system, ensuring durability and stability.

Design Considerations for Optimal Acoustic Performance

Designing an effective acoustic steel profile system requires careful consideration of several factors. The first is the desired level of sound reduction, often expressed in Sound Transmission Class (STC) ratings. Higher STC ratings indicate better sound insulation. The choice of steel profile, its thickness, and spacing directly impact the system’s performance. The type and density of the sound-absorbing material used within the air gap are also crucial. Furthermore, the system’s overall construction, including sealing and connections, plays a significant role in preventing sound leakage. Proper design also considers the frequency range of the noise being addressed, as different materials and designs are more effective at attenuating certain frequencies. Consultations with acoustic engineers are often recommended for complex projects to ensure optimal design and performance.

Installation Techniques and Best Practices for Acoustic Steel Profile Systems

Proper installation is critical to achieving the intended acoustic performance of the system. The process generally involves fixing the steel profiles to a supporting structure, ensuring a secure and vibration-free connection. The sound-absorbing material is then carefully placed within the cavity created by the profiles. Careful attention must be paid to sealing all gaps and joints to prevent sound bridging. This may involve using acoustic sealant or gaskets. The chosen cladding material, whether drywall, plasterboard, or another material, is then affixed to the steel profiles, completing the system. Experienced installers are crucial for ensuring a flawless installation, avoiding common mistakes that can compromise the system’s effectiveness. Regular quality checks throughout the installation process are essential.

Applications of Acoustic Steel Profile Systems: Where They Shine

Acoustic steel profile systems find applications across a wide range of environments where noise control is paramount. They are frequently used in:

- Commercial Buildings: Offices, hotels, and retail spaces benefit from reduced noise levels, improving productivity and customer experience.

- Industrial Settings: Factories and workshops can significantly reduce noise pollution affecting worker health and safety.

- Residential Construction: Apartment buildings and houses can achieve enhanced sound insulation between units or floors.

- Recording Studios and Home Theaters: These spaces require exceptional sound isolation, making acoustic steel profile systems ideal for creating controlled acoustic environments.

- Transportation Infrastructure: Noise barriers constructed using these systems can effectively reduce traffic noise impacting nearby communities.

These systems offer a flexible and adaptable solution, capable of being integrated into various architectural designs.

Benefits of Choosing Acoustic Steel Profile Systems

Several key advantages make acoustic steel profile systems a compelling choice for noise control projects:

- High Sound Reduction: They offer superior sound insulation compared to traditional methods.

- Durability and Longevity: The steel structure ensures long-lasting performance and resistance to damage.

- Versatility and Adaptability: They can be integrated into various designs and applications.

- Fire Resistance: Steel profiles inherently contribute to fire safety.

- Improved Thermal Insulation: In some cases, the air gap and insulation material can also improve thermal performance.

- Cost-Effectiveness: While the initial investment may be higher, the long-term benefits often outweigh the cost.

These benefits make acoustic steel profile systems a valuable investment for creating quieter, more productive, and healthier environments.

In conclusion, acoustic steel profile systems represent a significant advancement in noise control technology. By understanding their design, installation, benefits, and applications, architects, engineers, and builders can leverage these systems to create spaces where sound is effectively managed, leading to improved comfort, productivity, and overall well-being.

SEO Tags:

- Acoustic Steel Profiles

- Soundproofing Steel Systems

- Noise Reduction Solutions

- Steel Profile Acoustic Design

- Building Acoustic Solutions