Selecting the appropriate piping system is paramount in any energy project. From oil and gas transmission to renewable energy infrastructure, the choice of pipe significantly impacts safety, efficiency, longevity, and overall project cost. This comprehensive guide will navigate you through the critical considerations for choosing the right pipe, ensuring your project’s success.

1. Material Matters: Selecting the Right Pipe Material

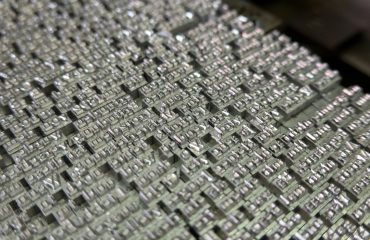

The material of the pipe is the foundational decision. Different materials offer unique properties, impacting their suitability for specific applications. Common materials include:

- Steel: A workhorse in the energy industry, steel pipes offer high strength, durability, and resistance to high pressures. However, they can be susceptible to corrosion, requiring protective coatings or specialized alloys like stainless steel.

- High-Density Polyethylene (HDPE): A popular choice for gas distribution and water pipelines, HDPE pipes are lightweight, flexible, and highly resistant to corrosion. Their flexibility makes them ideal for challenging terrains.

- Polyvinyl Chloride (PVC): Often used in less demanding applications, PVC pipes are cost-effective and corrosion-resistant. Their lower pressure rating limits their use in high-pressure energy projects.

- Fiber Reinforced Polymers (FRP): These composite pipes offer high strength-to-weight ratios and excellent corrosion resistance. They are a viable alternative to steel in certain corrosive environments.

- Ductile Iron: Known for its strength and durability, ductile iron pipes are frequently used in water distribution systems and some industrial applications. Their resistance to corrosion is good, but not as high as HDPE or FRP.

The choice of material depends heavily on factors like the transported fluid (oil, gas, water, steam), pressure requirements, environmental conditions (soil type, temperature), and project budget.

2. Pressure’s On: Understanding Pressure Ratings and Design Codes

Pipes are designed to withstand specific pressures. The pressure rating, often expressed in pounds per square inch (psi) or bar, is a critical factor. Exceeding the pressure rating can lead to catastrophic failures. Design codes, such as ASME B31.4 (Pipeline Transportation Systems) and ASME B31.8 (Gas Transmission and Distribution Piping Systems), provide guidelines for pipe selection and installation based on pressure, material, and operating conditions. It’s crucial to adhere to these codes to ensure safety and compliance.

Factors influencing pressure rating selection include the maximum operating pressure of the system, safety factors, and potential pressure surges. Proper pressure calculations, performed by qualified engineers, are essential to avoid under- or over-designing the pipeline.

3. Sizing Up: Determining the Optimal Pipe Diameter

The diameter of the pipe directly impacts the flow rate and pressure drop within the system. An undersized pipe can lead to excessive pressure drops and reduced efficiency, while an oversized pipe increases material costs and may create other engineering challenges. Accurate hydraulic calculations, utilizing software like PIPE-FLO or similar, are necessary to determine the optimal pipe diameter based on the required flow rate, fluid properties, and acceptable pressure drop.

Furthermore, future expansion should be considered. Choosing a slightly larger diameter might accommodate future increases in demand, preventing costly replacements or upgrades later in the project’s lifecycle.

4. Beyond the Basics: Considering Environmental Factors and Regulations

Environmental considerations are crucial in energy projects. Pipe selection must account for the potential impact on soil, water, and air quality. Regulations related to pipeline construction, operation, and maintenance vary by region and jurisdiction. Compliance with these regulations is mandatory, and failure to comply can lead to significant penalties.

Factors to consider include the potential for soil erosion, groundwater contamination, and greenhouse gas emissions. Choosing environmentally friendly materials and employing environmentally responsible construction practices are essential for sustainable energy projects.

5. Installation and Maintenance: Long-Term Considerations

The ease of installation and long-term maintenance requirements are often overlooked but equally important factors in pipe selection. Some materials are easier to install than others, impacting labor costs and project timelines. Regular maintenance, including inspections and repairs, is essential to ensure the continued safe and efficient operation of the pipeline.

The chosen pipe material’s resistance to corrosion, its susceptibility to damage from external factors, and the availability of skilled labor for installation and maintenance are all factors that should be considered before making a final decision.

By carefully considering these factors, energy project managers can make informed decisions about pipe selection, ensuring the safety, efficiency, and long-term success of their projects.

Tags: energy pipes, pipeline selection, pipe material, pressure rating pipes, pipeline diameter