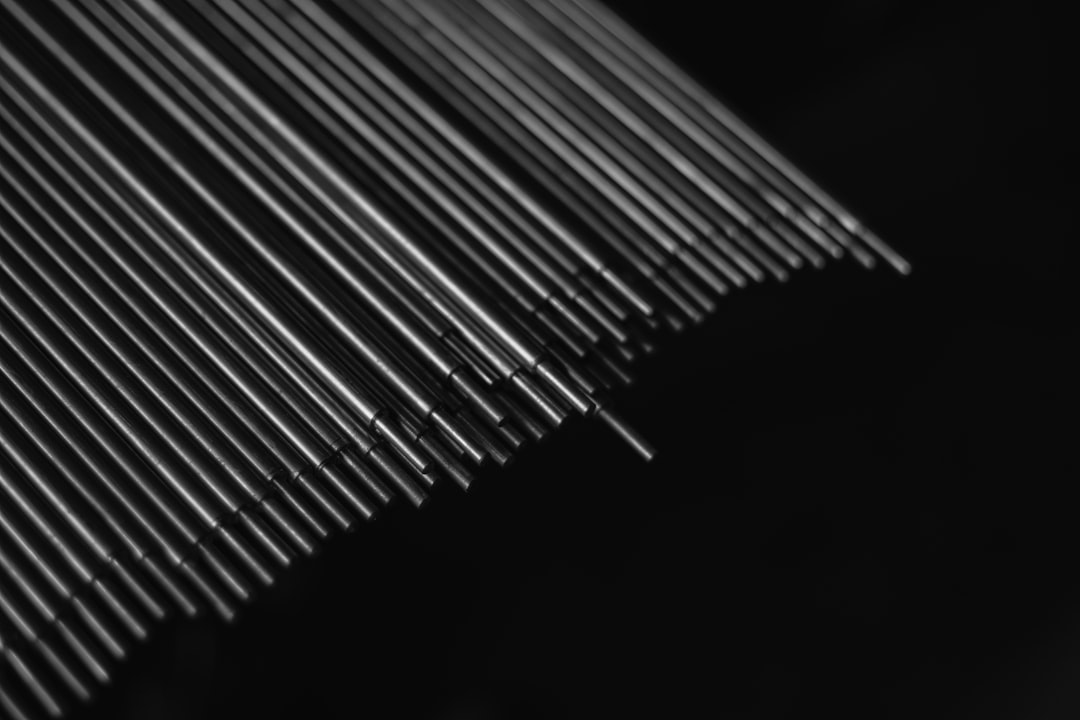

Annealed wire, a metal wire that has undergone a heat treatment process called annealing, boasts exceptional ductility and malleability. This makes it incredibly versatile and suitable for a wide array of applications across various industries. Understanding the unique properties of annealed wire is key to appreciating its widespread use.

1. Annealed Wire in Electrical Applications

One of the most prominent uses of annealed wire lies in the electrical industry. Its high conductivity, particularly when it’s made from copper or aluminum, makes it ideal for conducting electricity with minimal energy loss. Annealing reduces the internal stresses within the metal, improving its ability to carry current without overheating or breaking. This is crucial in applications such as:

- Wiring in homes and buildings: Annealed copper wire is the backbone of electrical systems in residential and commercial structures, safely distributing power to various outlets and appliances.

- Automotive wiring: The reliability and flexibility of annealed wire are essential for the complex wiring harnesses found in modern vehicles.

- Power transmission lines: While often larger gauge wires are used, the annealing process is still crucial for ensuring the durability and conductivity of these lines, even under immense stress.

- Electronic components: In smaller electronic devices, the fine annealed wire is used for intricate circuitry and connections.

2. Annealed Wire in Spring Manufacturing

The enhanced ductility of annealed wire makes it a preferred material for spring manufacturing. Its ability to withstand repeated bending and stretching without fracturing is critical for the performance of springs in various applications. The annealing process carefully controls the wire’s tensile strength and elasticity, ensuring consistent spring characteristics. This is vital in:

- Automotive suspensions: Helical springs in vehicles rely on annealed wire’s resilience to absorb shocks and vibrations.

- Mechanical components: From small clock springs to larger industrial springs, annealed wire provides the necessary flexibility and strength.

- Medical devices: The biocompatibility of certain annealed metal wires makes them suitable for use in medical implants and devices requiring flexibility and durability.

- Aerospace applications: High-quality annealed wire is crucial in aerospace components where reliability and resistance to fatigue are paramount.

3. Annealed Wire in the Manufacturing of Wire Mesh and Fencing

Annealed wire’s malleability lends itself perfectly to the creation of wire mesh and fencing. The process of weaving or welding annealed wire into mesh structures requires a material that can be easily shaped and manipulated without breaking. This is crucial for creating:

- Security fencing: Annealed steel wire is commonly used for constructing robust and durable security fences.

- Wire mesh for industrial applications: From filtering systems to reinforcement structures, annealed wire mesh offers strength and versatility.

- Agricultural fencing: Annealed wire is used extensively in agricultural settings to create fences for livestock and crop protection.

- Decorative wire mesh: The malleability of annealed wire allows for the creation of decorative and artistic wire mesh structures.

4. The Role of Annealed Wire in Welding and Brazing

In welding and brazing applications, annealed wire serves as a crucial filler material. Its clean surface and consistent properties ensure a strong and reliable weld. The annealing process minimizes impurities and ensures uniform flow during the welding process. This is particularly important in:

- Joining dissimilar metals: Annealed wire can facilitate the joining of metals with different melting points.

- Repairing damaged components: Annealed wire can be used to repair cracks or other damage in metal components.

- Creating intricate metal structures: Annealed wire’s ability to flow smoothly during welding makes it ideal for creating complex shapes.

- High-precision welding: The consistent properties of annealed wire are crucial for achieving high-precision welds.

5. Choosing the Right Type of Annealed Wire: Material and Gauge Considerations

The selection of annealed wire depends heavily on the specific application. Different materials, such as copper, steel, aluminum, and various alloys, each offer unique properties. The gauge of the wire, which refers to its diameter, also plays a crucial role. Thicker gauge wires offer greater strength, while thinner gauges provide greater flexibility. Careful consideration of both material and gauge is essential to ensure the wire meets the demands of the application.

Understanding the interplay between these factors is crucial for selecting the optimal annealed wire for any given project. Factors such as required tensile strength, conductivity, corrosion resistance, and cost all contribute to the decision-making process.

In conclusion, annealed wire’s versatility stems from the controlled heat treatment process that enhances its inherent properties. Its widespread use across numerous industries highlights its importance as a fundamental material in modern manufacturing and technology.