The construction industry is a significant contributor to global greenhouse gas emissions. However, a surprising champion in the fight for sustainable building practices is steel. Often perceived as an environmentally unfriendly material, steel, when produced and utilized responsibly, offers a compelling case for its role in creating a greener future for construction.

1. The Carbon Footprint of Steel: A Closer Look

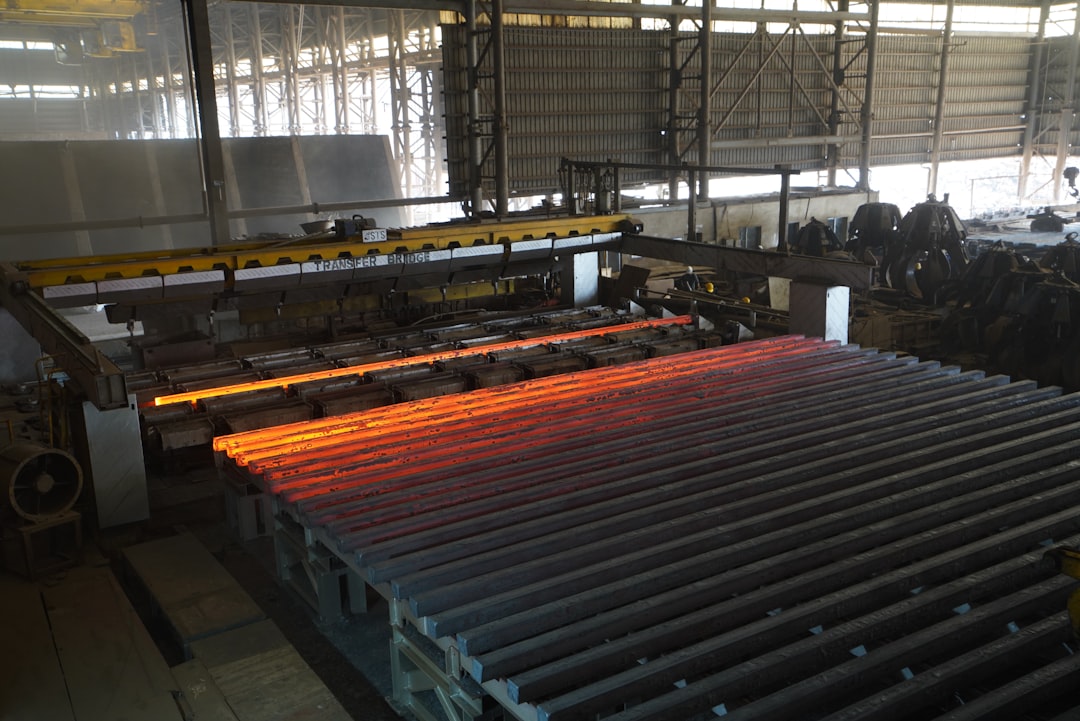

It’s crucial to acknowledge that steel production does involve carbon emissions. The process of smelting iron ore in blast furnaces is energy-intensive and releases CO2. However, significant advancements are being made to reduce this footprint. The use of electric arc furnaces (EAFs), which utilize scrap steel as their primary feedstock, drastically reduces carbon emissions compared to traditional blast furnaces. EAFs can reduce CO2 emissions by up to 70% compared to the traditional method. Furthermore, innovations like carbon capture and storage (CCS) technologies are being implemented to further minimize the environmental impact of steel production.

Furthermore, the embodied carbon – the carbon emitted throughout a material’s lifecycle, from extraction to manufacturing – of steel can be offset by its long lifespan and recyclability. A well-designed steel structure can last for decades, minimizing the need for frequent replacements and associated carbon emissions.

2. Recycled Steel: A Circular Economy Champion

Steel’s remarkable recyclability is a key factor in its sustainability profile. Steel can be recycled endlessly without losing its properties, making it a truly circular material. This significantly reduces the demand for virgin materials and minimizes the environmental impact associated with extraction and processing. In fact, the steel industry boasts one of the highest recycling rates of any material globally. Using recycled steel in construction projects demonstrably lowers the overall carbon footprint of the building.

The increased use of recycled steel not only reduces reliance on new resources but also decreases landfill waste, contributing to a cleaner environment. This closed-loop system makes steel a truly sustainable choice for environmentally conscious construction projects.

3. Lightweight Steel Construction: Optimizing Resource Use

Lightweight steel construction techniques offer significant sustainability advantages. These methods utilize high-strength, low-alloy steels to create lighter, more efficient structures. This reduces the amount of material required for a project, leading to lower transportation costs and emissions. The reduced weight also translates to lower foundation requirements, potentially saving on materials and energy during the construction phase.

Furthermore, the precision and speed of steel construction processes minimize construction time and waste. Prefabrication techniques, often employed in lightweight steel construction, allow for efficient off-site manufacturing and assembly, reducing on-site disruption and waste generation.

4. Durability and Longevity: Reducing the Need for Replacement

Steel structures are known for their exceptional durability and longevity. They are resistant to fire, pests, and weathering, resulting in longer lifespans compared to some other building materials. This extended lifespan reduces the need for frequent repairs, renovations, or replacements, minimizing the associated environmental impact over the building’s lifetime. The reduced need for future construction projects contributes significantly to the overall sustainability of the steel choice.

Proper maintenance and design considerations further enhance the longevity of steel structures, ensuring their resilience against environmental factors and extending their useful life for decades, if not centuries.

5. Steel’s Role in Sustainable Building Design

Steel’s versatility allows architects and engineers to design innovative and sustainable building forms. Its strength and flexibility enable the creation of lightweight, energy-efficient structures that optimize natural light and ventilation. Steel’s ability to support large spans also allows for the creation of open floor plans, maximizing space utilization and reducing the environmental impact of building materials.

Furthermore, steel’s compatibility with other sustainable materials, such as timber and recycled concrete, allows for the creation of hybrid structures that combine the strengths of various materials for optimal environmental performance. The integration of steel into sustainable building design strategies contributes to the creation of environmentally responsible and aesthetically pleasing structures.

In conclusion, while the steel production process does have an environmental footprint, its inherent recyclability, durability, and the advancements in production methods are making it an increasingly sustainable choice for the construction sector. By embracing responsible sourcing, innovative construction techniques, and a focus on the circular economy, the construction industry can harness the sustainable strength of steel to build a greener future.

SEO Tags:

Sustainable Construction, Steel Construction, Green Building Materials, Recycled Steel, Sustainable Steel