Modern architecture demands innovative and efficient structural solutions. IPE steel beams, with their distinctive I-shaped profile, are increasingly becoming the material of choice for architects and engineers seeking strength, versatility, and aesthetic appeal. This comprehensive guide explores the multifaceted role of IPE beams in contemporary building design.

Understanding the IPE Beam Profile

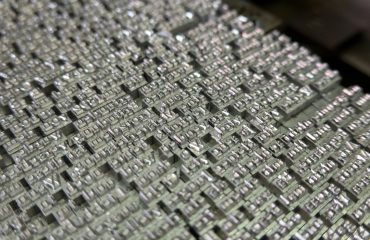

IPE beams, originating from the European standard, are hot-rolled steel sections characterized by their distinctive I-shape. This profile maximizes strength-to-weight ratio, making them ideal for spanning large distances while minimizing material usage. The “I” shape is incredibly effective at resisting bending moments, a crucial factor in supporting loads across open spaces. The flange width and depth of the beam vary depending on the size designation (e.g., IPE 100, IPE 180, IPE 300, and so on), allowing for precise selection based on specific structural requirements. The precise dimensions are standardized, ensuring compatibility and ease of calculation during the design phase. Their consistent quality and precision also contribute to faster and more efficient construction processes.

IPE Beams: Advantages in Modern Architectural Design

The popularity of IPE beams in modern architecture stems from several key advantages:

- High Strength-to-Weight Ratio: IPE beams offer exceptional strength relative to their weight, allowing for longer spans with less material compared to other structural elements. This is particularly beneficial in contemporary designs emphasizing open spaces and minimal support structures.

- Versatility in Applications: From supporting floors and roofs to creating impressive cantilevered structures, IPE beams adapt seamlessly to diverse architectural needs. Their adaptability extends to various building types, from residential and commercial structures to industrial facilities.

- Design Flexibility: The clean lines and consistent profile of IPE beams complement modern aesthetics. They can be easily integrated into both minimalist and complex designs, providing a structural backbone without compromising the overall architectural vision.

- Sustainability: Steel is a highly recyclable material, making IPE beams a sustainable choice in line with environmentally conscious construction practices. Their durability also contributes to the longevity of the structure, reducing the need for frequent replacements.

- Cost-Effectiveness: While the initial cost might seem higher compared to some other materials, the high strength-to-weight ratio often leads to material savings and reduced labor costs during installation. The long lifespan further reduces lifecycle costs.

Design Considerations for IPE Beam Integration

Successfully integrating IPE beams into a modern architectural design requires careful consideration of several factors:

- Load Calculations: Accurate load calculations are crucial to determine the appropriate size and spacing of IPE beams. This involves factoring in dead loads (the weight of the structure itself), live loads (occupancy loads, furniture, etc.), and any other relevant forces.

- Span Lengths: The span length directly influences the required beam size. Longer spans necessitate larger, stronger beams to ensure structural integrity. Software simulations and expert engineering calculations are essential for accurate determination.

- Connections and Supports: The method of connecting IPE beams to columns and other structural elements is critical. Welding, bolting, and other connection techniques must be carefully chosen to ensure strength and stability. The design should account for stress concentrations at the connection points.

- Fire Protection: Depending on the building’s function and location, fire protection measures may be necessary for the IPE beams. This can involve applying fire-resistant coatings or encasing the beams in protective materials.

- Corrosion Protection: To ensure longevity, IPE beams often require protection against corrosion, particularly in outdoor or humid environments. This is typically achieved through galvanization, painting, or other appropriate surface treatments.

IPE Beams and Sustainable Building Practices

The use of IPE beams aligns well with sustainable building practices. Steel is a highly recyclable material, making it a responsible choice in terms of resource management. The durability of steel structures contributes to reduced maintenance and a longer building lifespan, minimizing the environmental impact over the building’s lifecycle. Furthermore, the efficient design afforded by IPE beams can lead to material savings, reducing the overall environmental footprint of the construction project. The reduced transportation needs due to the high strength-to-weight ratio also contribute to lower carbon emissions.

Case Studies: IPE Beams in Iconic Modern Structures

Numerous iconic modern structures demonstrate the versatility and strength of IPE beams. From expansive open-plan offices showcasing impressive spans to museums featuring dramatic cantilevered elements, IPE beams provide the structural foundation for innovative and visually striking designs. Researching these case studies provides valuable insights into the practical applications and design possibilities offered by IPE steel beams in real-world projects. Analyzing the design choices, structural calculations, and construction methods employed in these projects offers valuable learning opportunities for architects and engineers.

In conclusion, IPE steel beams represent a powerful and versatile tool for shaping the future of modern architecture. Their strength, design flexibility, and sustainability make them an increasingly popular choice for architects and engineers seeking to create innovative and efficient structures.