Navigating the complex world of European manufacturing standards, particularly those under the EN (European Norm) umbrella, can feel like traversing a labyrinth. This guide provides a clear path, breaking down the key aspects of manufacturing to meet EN standards, ensuring your products are safe, reliable, and legally compliant within the European market.

1. Identifying Relevant EN Standards for Your Product

The first, and arguably most crucial, step is identifying which EN standards apply to your specific product. EN standards cover a vast range of products and processes, from electrical safety (EN 60335) to machinery safety (EN ISO 13849) and environmental protection (EN ISO 14001). A thorough investigation is essential. This often involves consulting the official websites of standardization bodies like CEN (European Committee for Standardization) and national standardization organizations. You’ll need to consider factors such as:

- Product Type: What is the intended use of your product? This will heavily influence the relevant standards.

- Materials Used: The materials used in manufacturing can determine compliance requirements.

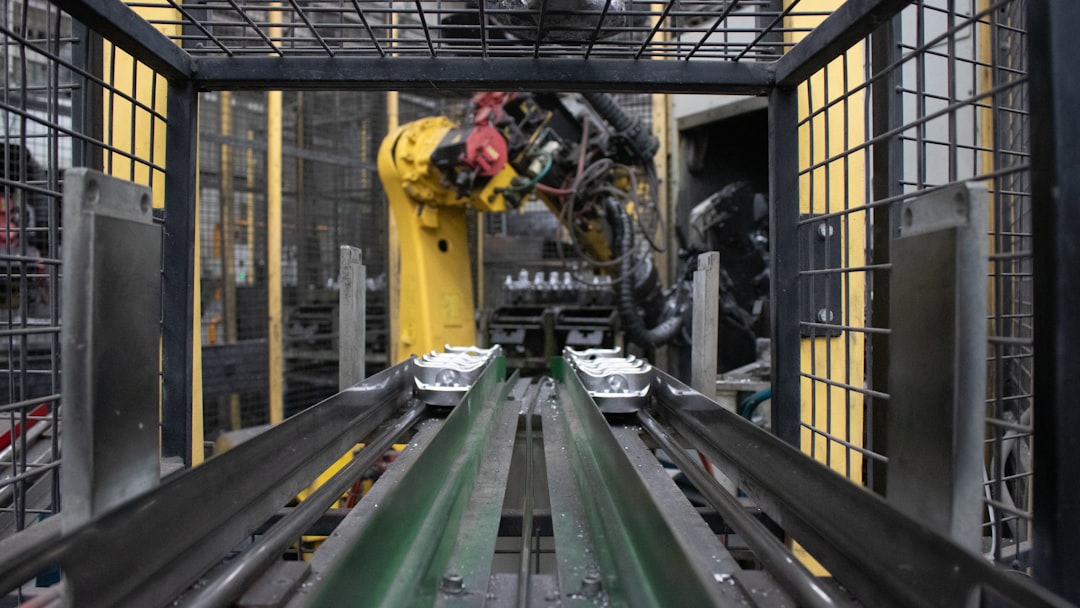

- Manufacturing Processes: Certain manufacturing processes might necessitate specific safety and quality standards.

- Target Market: Understanding the specific regulations in your target European markets is vital.

Failing to correctly identify the relevant standards can lead to costly rework, product recalls, and legal repercussions. Seeking expert advice from a standards compliance consultant can be invaluable in this stage.

2. Implementing EN Standards Throughout Your Manufacturing Process

Once the relevant EN standards are identified, their implementation throughout your manufacturing process is paramount. This requires a systematic approach, integrating the standards into every stage, from design and procurement to production and quality control. Key aspects include:

- Design for Compliance: Incorporating EN standards into the product design phase ensures compliance from the outset. This avoids costly modifications later in the process.

- Material Selection: Choosing materials that meet the specified requirements of the relevant EN standards is crucial for both safety and performance.

- Process Control: Implementing robust quality control procedures throughout the manufacturing process ensures consistent adherence to the standards.

- Documentation: Maintaining meticulous documentation of every stage, including material certifications, test results, and process parameters, is essential for demonstrating compliance.

This requires a well-defined quality management system (QMS), often based on ISO 9001, which provides a framework for consistent and efficient implementation of EN standards.

3. Rigorous Testing and Verification Procedures

Thorough testing is crucial for demonstrating compliance with EN standards. This involves a series of tests designed to verify that the product meets the specified requirements. The nature and extent of testing will vary depending on the relevant standards. This might include:

- Safety Testing: Evaluating the product’s safety features to ensure they meet the required levels of protection.

- Performance Testing: Assessing the product’s functionality and performance characteristics to ensure it meets the specified parameters.

- Environmental Testing: Testing the product’s resilience to various environmental conditions such as temperature, humidity, and vibration.

- EMC Testing (Electromagnetic Compatibility): Verifying that the product does not interfere with other electronic devices and is not susceptible to electromagnetic interference.

These tests should be conducted by accredited testing laboratories to ensure impartiality and credibility. The test results form a critical part of the compliance documentation.

4. Securing EN Certification: A Mark of Quality and Compliance

While not always mandatory, obtaining EN certification from a notified body significantly enhances market credibility and demonstrates a commitment to compliance. A notified body is an independent organization designated by a national authority to assess conformity with EN standards. The certification process typically involves:

- Factory Inspection: A thorough inspection of the manufacturing facilities to verify the implemented quality management system and manufacturing processes.

- Product Testing: Independent testing of the product by the notified body to confirm compliance with the relevant EN standards.

- Documentation Review: A comprehensive review of all relevant documentation to ensure completeness and accuracy.

Securing EN certification provides a competitive edge, opens doors to new markets, and reassures customers of the product’s quality and safety.

5. Continuous Improvement and Staying Ahead of the Curve

Meeting EN standards is not a one-time event; it requires a commitment to continuous improvement. Regularly reviewing and updating your processes, staying informed about changes to standards, and proactively addressing any identified non-conformances are crucial for maintaining compliance. This involves:

- Regular Audits: Conducting internal audits to identify areas for improvement in your QMS and manufacturing processes.

- Monitoring Standards Updates: Staying informed about changes and updates to relevant EN standards to ensure ongoing compliance.

- Corrective and Preventive Actions (CAPA): Implementing a robust CAPA system to address any identified non-conformances and prevent recurrence.

- Employee Training: Ensuring that all employees involved in the manufacturing process are adequately trained on the relevant EN standards and procedures.

By embracing continuous improvement, manufacturers can not only ensure ongoing compliance but also enhance product quality, efficiency, and competitiveness.

Meeting EN standards requires dedication, thoroughness, and a commitment to quality. By following these steps, manufacturers can navigate the complexities of EN standards and confidently bring safe, reliable, and legally compliant products to the European market.

SEO Tags:

EN Standards, European Norms, Manufacturing Compliance, Quality Management System, Product Certification